|

|

Post by thruxton on Feb 20, 2024 7:56:28 GMT

It’s Beige ….. I’ll take it! I’m over 60.

Seriously.

Heroic work. Full marks for utter bonkers determination and end results.

Regards.

Rich.

|

|

|

|

Post by Bilbo on Feb 21, 2024 11:17:03 GMT

It’s Beige ….. I’ll take it! I’m over 60. Seriously. Heroic work. Full marks for utter bonkers determination and end results. Regards. Rich. Haha cheers mate, it was definitely worth the slog I think. |

|

|

|

Post by Bilbo on Feb 22, 2024 1:07:50 GMT

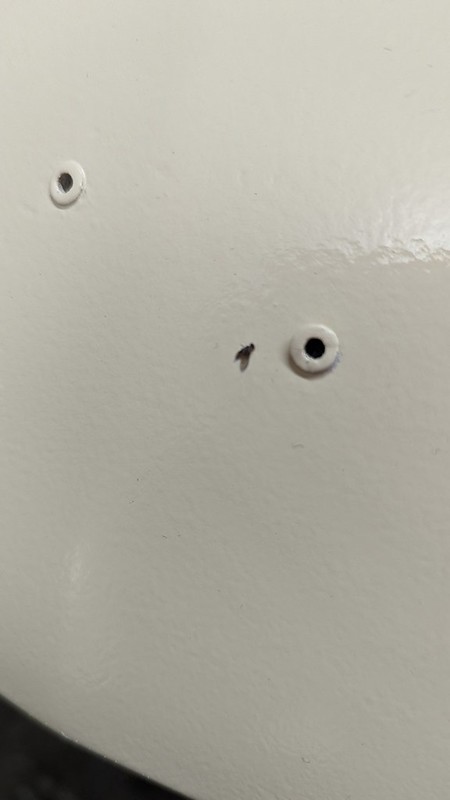

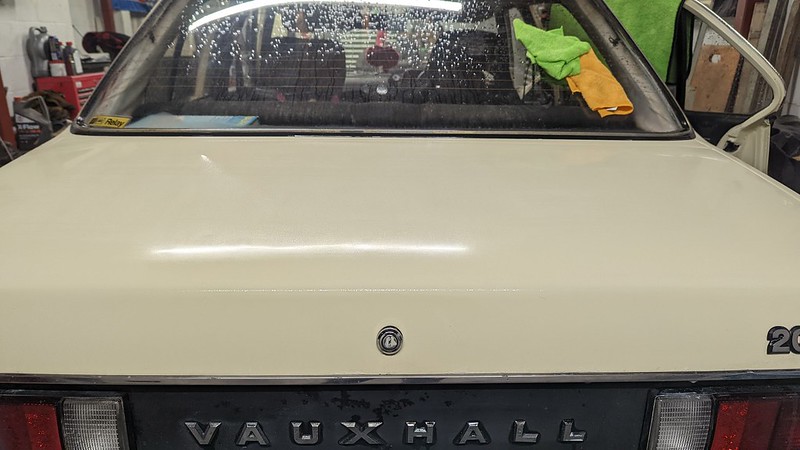

Ok so yesterday I reassembled the car. Pulling the masking off was both satisfying and terribly unnerving at the same time. Once that was done I went into my storage area and piece by piece brought the parts downstairs and reattached them. Slightly unnerving on new paint, but even with a couple of slips while putting things back on, the paint was super resilient already and didn't scratch or chip at all, which was great. Anyway it turned into a total ballache when it came to the door handles. The attaching rods for the door pulls are very basic, but the end hook is impossible to attach with the handle placed in the door. Instead you have to pull the handle open, bring it up to the door, push the rod out of the handle hole in the door, and angle the handle to push the pull rod into place. Right next to brand new paint, like a few mm away. Absolutely terrifying. Plus the nuts for the rear door are so far to the rear of the door they are almost impossible to actually get back on without dropping them into the door void at least a dozen times. Anyway, all good and it is now done and I am never touching those handles ever again for any reason 😂 Oh yeah a fly decided to fly into the paint on top coat spraying day, so thanks for that.  Note the orange peel. I will get that sorted soon. As for the fly, luckily for me directly under the front Vauxhall badge, so the imperfection in the paint after removing it is out of sight, out of mind. Speaking of the Vauxhall badge:  I love this combo, it compliments and contrasts the paint so well. And yeah I didn't paint the engine bay. Once I have cleaned the bay up a bit and got a red interior I think it's going to suit it being red as well. I did all the wing edges and bonnet shuts cream so it doesn't look weird, I quite like it this way after looking at it. Drove it home and here it is:  Needs a wet sand and polish of course, but I'm pretty happy with this. I think it looks great. But much the same as when I got my MX-5 painted, the black roof had to go immediately and I got a red one. In this case a red interior is definitely needed to finish it off now, it's lacking colour for my taste, and that'll make it really pop, especially in the sun. I am keeping an eye out! As for the finish and mask lines etc. all the door jamb ones are hidden by the rubber seals as planned, the only areas that need attention are the left rear arch on the edge of the chrome trim has 2 little areas just by the door that need a little touch up. The windscreen trim tape worked really well, the rear screen is absolutely perfect with no visible red at all anywhere. The front screen right at the top I should have pulled the trim tape a little tighter as there is a very thin bit of visible red on it, but honestly it's not that bad. Small touch up will work. I have a colour matched rattle can from Jawel where the paint came from already, so I will likely just either use this, or spray it into the cap and use a tiny brush to correct these areas, they are very minor to be honest. Other good news is that ominous red tape over the top of the windscreen seal, I obviously removed it all with a blade before painting, and under it was the tiniest little bit of surface corrosion right in the center which disappeared with mild sanding, and it has since rained and the screen doesn't leak at all anywhere, so I genuinely don't know why it was there. Very odd. I will keep an eye on it. |

|

|

|

Post by Bilbo on Feb 28, 2024 0:42:24 GMT

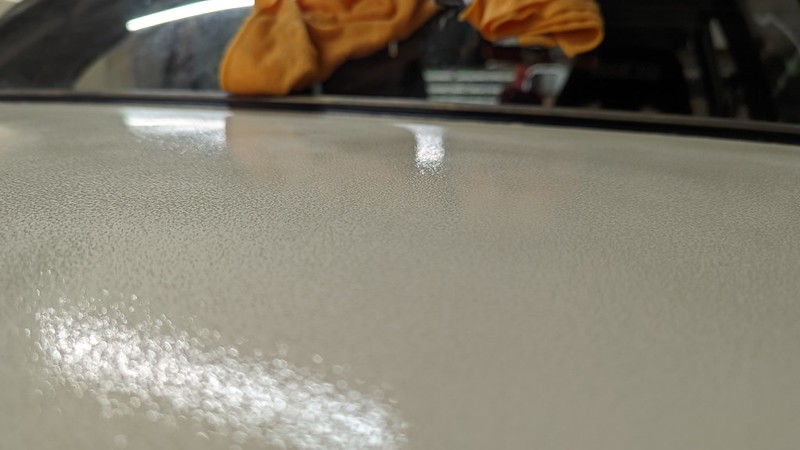

Ok so been driving the car about and I really love this colour. Before and after:  And next to the 86 in the same colour:  It's in daily duty again and it's so cool walking out of anywhere to see it in this colour. I just love the red badge.  Nervous about people parking next to me though. Please stay away, why must everyone park next to you, no matter where you park, or how empty the place is 😂 Anyway, onto some work. So, the orange peel. I hadn't shown any close ups of the boot/roof/bonnet as it looks even worse on camera than in person and to be honest I was almost embarrassed by it. But anyway here's the boot:  Bloody awful! So started off with some soapy water and 1200 grit. Taking the peel out surprisingly quick with this, I was shocked actually. So I flatted the worst of it off with 1200, then 1500, then 2000. Ultimately I needed to go a little bit further with the 1200 on the boot than I did, which I will address when I redo it soon.  It was looking better as it flatted off the peaks, but still work was needed. So we redid one spot of the boot on one side. Went over it for longer, up to 2000. Then cut on the machine with G3, another compound after, and then a polish. Just to see what we were left with. Not bad:  I mean it's a damn sight better than it was. Camera couldn't really pick it up but there's a lot of tiny swirl scratches in the tested area, which I'm not happy with. It's not a show pony but may as well do it right. So I have now decided to go up to 3000 before cutting back, so I've ordered some 2500 and 3000, I think this will leave the paint a lot more ready to be cut and polished without swirls when finished. Not done this before, and while I've only made a small bit of progress this evening was more of a learning phase to work out how the paint would take to the sanding, and what was required to get it where I want it. I'll be back at it on Thursday or Friday, and Saturday all day, so hopefully get the bulk of it done then. |

|

|

|

Post by dadbif on Feb 29, 2024 8:48:28 GMT

Great work, mind you don’t rub through though.

|

|

|

|

Post by Bilbo on Mar 1, 2024 12:27:16 GMT

Great work, mind you don’t rub through though. Cheers mate, I'm being as careful as possible. So far not too many issues, hopefully it'll stay that way! |

|

|

|

Post by Bilbo on Mar 1, 2024 12:27:35 GMT

So I've been carrying on with the wet sanding, and it's going alright. A lot to sort out, but it is slowly getting better. The roof was pretty bad as well:  I went with a new method as the hand sanding was getting tiresome, and it is working very well for the initial flat back. I have been using a DA, bought some ultra fine sanding discs and using it on a very low speed. Starting off with 1500, then 2000, then 3000. Of course wet, with a bit of soap to avoid excessive paint removal/scratches etc. It is working alright, this is after that process and then a cut back with a compound (no final polish as not happy with remaining texture):  The roof still looks orange peely, but it feels incredible to the touch now compared to before, like glass. The unit strip lights are incredibly unforgiving for stuff like this, when my mate took some of his Land Rover panels outside they look absolutely amazing in daylight, but the various ceiling lights show up every single imperfection. Boot is in roughly the same sort of state at the moment:  I think going forward I will stick to this method for the initial flat back, with the DA. But to prevent burn through I will get the last of the orange peel areas out by hand on each panel, far more control for the final bits of sanding that way. I don't expect it to be mint, but I want it to at least look decent, and it's worth the effort. You will notice in the photos all panel edges are still super rough, I will be doing all of these entirely by hand as I don't want panel edges to cut through the paint with the machine, not worth the grief. Oh yeah, here's the red engine bay:  Once it is cleaned up a bit, my newly painted cam cover is fitted, I've tidied some wiring, and fitted a red interior it will suit it really well. |

|

|

|

Post by Bilbo on Mar 4, 2024 10:38:12 GMT

Ok spent a load more hours on Saturday, and a bit of yesterday wet sanding and polishing. Overall gone pretty well. Here's a bit of a before and after, you can see the texture in the top of the wing, and then the clearer looking paint on the bonnet:  Got all of the doors and wings done as well. Pretty long job, but same process as before. 1200 up to 2000 on the DA on low/medium speed, followed by G3 compound on machine, and finished with a final polish:     Honestly not too bad. I'm just happy it looks gloss now at least 😂 There are some areas that could do with a little more, and a couple of panels I ideally want to polish a bit more, but overall I'm fairly happy. It feels like glass to the touch which is nice. I started by doing the final polish step with a foam Finishing pad on the machine, but I was getting what are known as "holograms", I have no idea why this was occurring, but I noticed it after doing the first panel, the boot, and immediately stopped using it. Likely operator error let's be honest, I have never done this before.  So I need to refinish the boot, but luckily this isn't present anywhere else. I have been doing the final polish step entirely by hand, so my shoulder is very achey today 😂 Just need to give it a proper wash now to get rid of any residue and whatnot and it should look good  Now I'm almost past this process I've learned a lot, the main thing being that I wish I just went for it and got a few runs putting the paint on a bit thicker than being scared of that. While I have got the worst of the texture out, there is still a fair bit of orange peel/pits all over, and in the areas I have really attacked it the paint is getting just a bit too thin to really remove it entirely. Ultimately it's fine, outdoors in the sun you can't even see it unless you're looking for it, but our unit strip lights really show up every single tiny imperfection. As I said to my painter mate when he came down the other day, I'm just glad the paint has adhered well and not reacted or just fallen off 😂 for a first time ever spraying a car I'd say this is acceptable. |

|

|

|

Post by Bilbo on Mar 11, 2024 11:06:27 GMT

Ok the car is looking well now. Needs a couple of paint touch ups in a few small areas, but overall it's looking glossy, and looks lovely when the sun comes out which is practically never since it's been done. Little bit of a polish on a couple of panels and a tiny bit of wet sand and buff in a couple of missed areas (not noticeable particularly) and it'll be good enough for me!  So now this process is 90 odd percent complete, I really needed some time off from paint, wet sanding, and all that. I'd never really liked the small trumpets on the ITBs. There was nothing really wrong with them as such, it was convenience more than anything as I had them lying around from my initial ITB setup on my old MX-5 and they slotted perfectly on the 750 bodies I am using now. But they're like 30 or 35mm. I ran 90mm ones on my old MX-5 and they were glorious. However me being me I don't like to drop £150+ on something before knowing if I actually want it or not, so I went about making something up of my own to try them out. So I went out and bought some pipe, ABS waste pipe to be precise. Chemical resistant and withstands temperatures much higher than say PVC, though to be honest my bay temperatures have been pretty low since I wrapped the exhaust. The trumpets only really get a little warm to the touch, even after a hard drive. Also it cost me £13 for 3m of pipe, so I couldn't really argue. We're currently sorting a new workbench at the unit, so here's how it looked:  I found a couple of people online who had posted about flaring/bellmouthing the ends of pipe like this for various purposes, such as bass reflex tubes on custom bass speaker boxes. The main challenge was finding the right "forming tool" from what we had lying around. As you can see above, a few failed attempts occurred after trying all sorts of things. The top of bottles. top of an empty rattle can etc. They all kind of bellmouthed the end out but not very well, and then I found the perfect thing. My mate's 46mm socket:  Perfect. I cut 4 pieces of pipe down to size. Gently heated the ends with the blowtorch, and then squared each one of them up and pressed them over the socket, resulting in a pretty decent bellmouth on each of them to aid airflow. The pipe has a 50mm inner diameter, which exactly matches the inlet internal diameter of my ITBs (they taper down to 40 odd at the head end). Obviously I needed to flare the ITB end of the stacks to slot them over the ports, so again I heated this end up, and then pushed them over the port on the throttle bodies. Once cooled each trumpet was a very tight interference fit onto the throttle bodies with no attachment clip/jubilee etc. they just push fit and they stay there, much like the original ali 30mm ones did. I then took them off, gave them a little key up, and sprayed them with black plastic paint on the outside, just because the white looked a bit weird to be honest. I went a bit big with them 😂 150mm long, approx. 15mm of that is the attachment point over the ports, and lets say 5mm or so on the bellmouth end from the flaring over. So 130mm ish actual length, +/- a couple of mm. Before:  After:   The plan is that these are temporary, obviously without dyno power runs it's impossible to really estimate what is best. General consensus seems to be short trumpets for high RPM HP, and longer trumpets for mid range torque. My mate has just acquired a TIG welder, so eventually I'd like to make these out of metal, and perhaps about 20-30mm shorter would be ideal as they're just a touch closer to the strut tower than I would really like. Good points: they don't get too hot, I really gave the car some grief on the way home and they haven't been affected, still in place, no issues with deforming or softening, they just stay there and work. They also sound ridiculous, even just cruising at low RPM, the growl from the ITBs is way more pronounced than before, and flat out they have a much deeper aggressive intake noise than before which sounds absolutely mental. Bad points: they're plastic. Let's be honest, even though they're black which is ok, they'd look far better made out of polished metal. Bit too long and a bit close to the strut tower, possibly affecting airflow. Maybe the final versions I will add a small bend to at the flange end to raise them a little. Honestly not too bad for a few quid, and they do look ridiculous at that length which I kind of love 😂 need to get my painted cam cover on now and tidy the bay a bit! |

|

|

|

Post by Bilbo on Mar 18, 2024 10:32:47 GMT

Right, so the plastic trumpets were a great success given their cost. Didn't deform, fall off, and they sounded great. I honestly thought I'd keep them for a bit longer but decided polished metal version are just so much better looking, so decided to get that done this weekend. Bought 4 pieces of hose connector polished ali, with a swaged end (intercooler type pipe). £9 each, same length as the plastic ones I made. Obviously the end was far too straight to be a good velocity stack, so I needed to form a bellmouth. It was going to take a bit more effort than simply heating plastic and forming them by hand, so I grabbed the blowtorch and the press and gave it a go. Started by forming the radius with a large socket. Once the ali was hot it wasn't too bad to roll the ends out slightly. Once this was done I flipped them over and pressed the end down into a flat plate a little to further flare the bellmouth. Now the radius on these ends isn't very large for a few reasons. Firstly flaring the ali further/wider would increase the chance of tearing the metal, also it's harder to form, especially as I am not skilled at metalworking at all. Also our press is pretty basic and the actual pressing part is p*ssed and a pain to work with. So I did what I could with what I have, here's my incredibly professional setup:  As I said, small bellmouth. I did some light reading from people far more skilled than I, and yeah a large radius stack is better for airflow, but we're talking small percentages. This is a road car, I reckon it won't be noticeable either way in reality. Anyway, I cut 2 small relief slits in the throttle body side, much like my original trumpets had, and they pushed on ok:  Not too shabby. There is a small ridge on the outside of each runner, so I hammered out the ends a little bit more on each of the new stacks, and then tapped them all on to each port. Cylinder 1 and 4 stacks are sitting just a little wonky, so I need to look at the end and adjust it a little to get it sitting straight like the other 2:   A touch too close to the strut tower for my liking, but they're not bad for under £40. Obviously a little excessive in length still, I think they'd be perfectly good about 20mm shorter than this. I think they look a lot better than the black ones, and the sound is utterly mental flat out, it's just stupid. I'll get some videos of it soon. Next up will be cleaning the bay up a bit, fitting my repainted cam cover, and sorting some leaks in the footwells I'm still having issues with. |

|

|

|

Post by boggissimo on Mar 19, 2024 11:56:04 GMT

Are they actually secured to the ITBs with anything? Just wonder if vibration will eventually shake them loose.

|

|

|

|

Post by Bilbo on Mar 19, 2024 15:22:39 GMT

Are they actually secured to the ITBs with anything? Just wonder if vibration will eventually shake them loose. Nah nothing at all. The rolled/swaged edge is slightly wider than the pipe itself, so we took the throttle bodies off the car and tapped them on with a hammer and block of wood. You can carry the throttle bodies by just holding one of the trumpets, I would be so shocked if they ever came off. Actually if I ever need to get them back off it's going to be a total pain haha. The original 35mm ones were only push fit type, and not as tight as these are, and they didn't come off in just under a year so I think I should be ok. |

|

|

|

Post by Bilbo on Apr 3, 2024 16:11:56 GMT

So not too much going on, not had much spare cash for stuff for the car lately. I've quit smoking so hopefully that'll free up some car money soon 😂 Been enjoying the new trumpets and doing a few small bits here and there though. Painted the spare cam cover ages ago, but not touched it since. Bought some little syringes and decided to infill the letters red. Same red as I used on the front badge, just something I found in the cabinet. Ford Radiant Red.  Realised the photo looks weird and the red is a bit blurry/overexposed. It actually looks pretty neat in person. Not sure if I like it, it's alright, but it is definitely an improvement on the oxidised one that is currently on there. Will get that fitted with a new OE cam cover gasket soon. Also gave it it's first wash since the respray. Noticed a couple of defects in the paint in small areas, but nothing too worrying to be honest.  Looking pretty good I think.  But I need red seats/red interior asap. I have found some red seats out of a mk3 MR2 that I think will look good. Pretty cheap and local enough, I may go get them and make them fit. Not too bulky, slight bucket seat look but not overly modern. Also they're red material, I'm not a fan of leather seats so all the red leather options I ignored. Either way the red needs to happen soon as the cream and black colour scheme isn't for me at all. I have my ticket for Sunday at Retro Rides Goodwood now, and I have applied for Players Classic too. They accepted it into concourse last year 😂 so surely I'll be accepted again this year you would think, now it has been painted and whatnot. It was a good show actually, some great stuff there. |

|

|

|

Post by Bilbo on Apr 11, 2024 13:16:54 GMT

Right, I like having a bucket seat, but the old Sparco has seen better days. I bought it for £60 about 7 years ago and it wasn't new then. Plus it isn't red. So I started looking around at red seat options. I thought about buying some red Sparco buckets, but I don't know, maybe just a little modern looking, and also I don't really have much cash at the moment. And the red retro seat offerings all looked uncomfortable, or too low backed for my liking (I like a headrest). So I started looking at OE seats from various cars. I discounted anything leather or bulky looking, so modern stuff with all electrical bases and stuff (i.e. very heavy and high seats). Came across red cloth MR2 seats, from the mk3 MR2. Thought they'd be a good option. Looked up the weight on some MR2 forums and they're fairly light, no electrical stuff in the base, from a small car so not going to be bulky. Then a pair popped up on Marketplace not a million miles from me for £120. Then they were £100. Then £80. I really couldn't say no, £80 for a pair of pretty good condition seats, can't argue!  Pretty good nick, bit of a bucket style, fairly supportive, on adjustable runners, and reclinable. Also the drivers seat has a twist knob to lower the seat base down for taller drivers, ideal! So then it came to fitting them. Took the Sparco out of the driver's side, and then worked out the height difference between the mount points. The left hand rails sit on a ledge of sorts, approx. 7cm higher than the right side mounts. So I needed a way to make up a mount extension to get the seat nice and level. I took the MX-5 side mount rails I had been using for the Sparco, and these seemed ideal. I only needed the right side mount. So I cut it down to about 7cm tall, cut the feet off of the right side runner, and welded it directly to the runner frame on the MR2 seat.   You can clearly see the height difference between the 2 sides here. I'm happy with the welding, I seam welded the entire length of the runner extension, so it is plenty strong. I may however add a little bit of lateral support to it in the form of a bracket of some kind, just for extra safety and peace of mind. Anyway with this done I needed to place it in the car. Roughly in place it sat level, so I was happy the rail was correct. The width of these runners is about 7cm wider than my previous setup, so I had to drill a couple of new floor holes for the bolts. With the Sparco I was using some large circular washers as spreader plates, but I feel these were just a little too thin material for my liking, so I've fitted some thicker spreader plates underneath for the seat bolts to bolt up to, and used Nyloc nuts to make sure they stay put:  3 of the mount points use these plates now, and the rear right uses one of the original strengthening pieces that the original seats bolted through, so that's all good. Now the left side rails I kept the original MR2 feet on, I just bashed the front one flat with a big hammer so it mated nicely to the floor. The rear left foot is actually transmission tunnel mounted sideways as opposed to the other 3. So once the other 3 mount points were bolted down I got a hole drilled into the tunnel, and had a look how to bolt it down effectively. There is a bit of a gap between the tunnel and the foot, so I added a very thick spacer so that when bolted down the seat foot and the tunnel are pressed hard against each other. Obviously added a spreader on the other side to give it some strength, and it all bolted on nicely.  The seat feels super solid now it's all torqued down, I'm pretty happy with it. Removed the seat mounted belt buckle they came with as my Vauxhall seatbelts won't clip into them, and I am using my original tunnel mounted buckles. They sit at the right height so the belt feels nice and tight against you when clipped in.   The passenger side is slightly different as the raised floor is only on the rear right, but similar principle, so I will get that done as well this week. First piece of the red interior is done. Need to sort the rest when money allows and I find some red interior pieces. I'll get some proper photos when they're both in, I think it's going to complement the paint quite well, certainly did on my MX-5. The seat is quite nice, you don't sit as deep in it as the Sparco, which takes some getting used to, but it's still marginally lower than the OE seat when the height adjustment knob is bottomed out. It is slightly too high for my liking, but that's just because I'm used to almost sitting on the floor with any seats I fit into my cars 😂 |

|

|

|

Post by Bilbo on Apr 14, 2024 1:46:53 GMT

Ok so got the passenger seat in. Was a bit awkward on that side, as just the right rear of the seat sits on a raised part of the floor, and the rest is all flat on the lowest part of the floor. Used the other side of the MX-5 side mount rails, the same as I did for the driver's side, and then made up some angle and box section for the front right corner. Was a bit fiddly getting it to sit straight few new floor holes drilled. Was pretty much the same s the driver's seat though, took the buckle out, and got the rear foot bolted through the tunnel again, just like with the driver's side. All bolts have spreader plates and Nylocs, seat feels super sturdy in there, I'm happy with it.  This was during test fit, just making sure they sat roughly level and the same distance from the pillars. And yes that is an Arnie poster on the unit door 😂 I have no idea where it came from, but it just appeared one day, so it was put up and has been there ever since haha. I think they look quite sporty without being way too modern looking:  Definitely a more aggressive look, I like them. They really go with the cream as well I think.   Now the passenger side has proper sliding rails I had to move the extinguisher, so I put it in a slightly more convenient place for super quick access, just bolted to the tunnel. Doesn't get in the way of passenger's legs that much:  Other red stuff will come in time, I want it as red as the ridiculously over the top OE red interior eventually Might get some red floor mats, will be a cheap way to brighten up the floor area at the front I think. |

|