|

|

Post by scottydugg on Aug 8, 2023 11:55:54 GMT

A lot of this style bolt directly to the gearbox, do you think that'd be the way to go? I'm guessing you'll need some form of isolation if it's chassis mounted? if you go off the gearbox with a frame you eliminate that need. could even solid mount in that instance?

|

|

|

|

Post by Bilbo on Aug 8, 2023 15:09:51 GMT

A lot of this style bolt directly to the gearbox, do you think that'd be the way to go? I'm guessing you'll need some form of isolation if it's chassis mounted? if you go off the gearbox with a frame you eliminate that need. could even solid mount in that instance? This is a very good point I hadn't taken into account, someone also raised this on the Manta page re: my diagram. The brace for gearbox onto the chassis is pretty beefy, with 2 very stiff rubber bushes on either side, going into the OE mount holes on the chassis. The shifter is almost directly above this mount, I'd hope there wasn't a lot of movement, but it is a good point. There will be movement in the box to some extent, as obviously I have rubber engine mounts and rubber bushes on the box mount. But I'm not sure if it would be enough to cause issues with a shifter that was hard mounted to the chassis on one end? Your solution of mounting it to the box on the front side would as you say remove this issue entirely, as the entire shifter mechanism could move independently of the chassis, and thus have no movement between the 2 mount points. I'll need to look into whether it is feasible on the top of the 5 box. |

|

|

|

Post by scottydugg on Aug 9, 2023 8:48:31 GMT

A lot of this style bolt directly to the gearbox, do you think that'd be the way to go? I'm guessing you'll need some form of isolation if it's chassis mounted? if you go off the gearbox with a frame you eliminate that need. could even solid mount in that instance? This is a very good point I hadn't taken into account, someone also raised this on the Manta page re: my diagram. The brace for gearbox onto the chassis is pretty beefy, with 2 very stiff rubber bushes on either side, going into the OE mount holes on the chassis. The shifter is almost directly above this mount, I'd hope there wasn't a lot of movement, but it is a good point. There will be movement in the box to some extent, as obviously I have rubber engine mounts and rubber bushes on the box mount. But I'm not sure if it would be enough to cause issues with a shifter that was hard mounted to the chassis on one end? Your solution of mounting it to the box on the front side would as you say remove this issue entirely, as the entire shifter mechanism could move independently of the chassis, and thus have no movement between the 2 mount points. I'll need to look into whether it is feasible on the top of the 5 box. Yeah only reason I asked was the gearbox swaps I've seen on LS engines on YouTube, they all have a frame that comes off the box and moves the new shifter into position. Sure there would be enough fixing points on the back of the gearbox if you're creative - maybe chuck in a bushed brace somewhere to stop it rattling itself to pieces. then you can run a straight shifter. |

|

|

|

Post by Bilbo on Aug 10, 2023 9:08:46 GMT

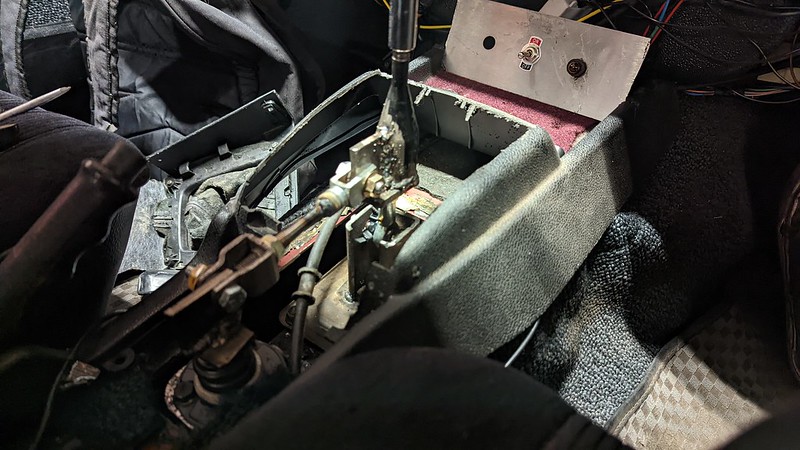

Ok, so decided to just get it done last night. I rigged up an absolutely terrible shifter to get to the unit, as all I had was the snapped shifter stub. It involved a 1/2" extension, reinforced tape, and cable ties. It was truly awful, but it got me there, so that's a win 😂 Anyway, based on the comments from a couple of people, including scottydugg (thank you), I decided my chassis mounted front was a bad idea. So I pulled all the sound deadening/carpet etc. out and took a look at the box. On the top of the box there is a little plate held on with 4 12mm bolts. Under this is the shifter rod that goes to the inside of the box. Some people do shorten the shifter into this location by cutting the rod down, but I wanted a solution I could easily swap to another box if I ever need to. So I took the plate out, and welded a piece of cut down box section to it. Drilled a hole through both sides of this new box section bracket, and found a weird bolt in the spares drawer that only had thread right at the head end. Used the makeshift drill/grinder lathe method to make the smooth round part smaller, so the rose joint could slip onto it.  The hole on the bolt head side is 12mm, and on the other side only 8mm, so the smooth end sits fairly tightly in the hole. You can see the nut holding it in on the inside, this keeps it in place. I had to do this as I had no appropriate bolts that had thread on the end that would actually be suitable for the rose joint I used. It looks a little odd, but it actually works very nicely. I drilled a hole in the bottom of my shifter and put a small piece of threaded bar in the bottom, which winds into the rose joint and allows the shifter to smoothly articulate 360 degrees as required, while keeping it anchored. Only thing I need to do is add a small spacer to the left of the rose joint to stop it moving to the left too far for 5th and reverse shifts. dadbif mentioned this, and was correct, lateral shifts need better control with this setup, this should sort it. For testing I just added some beefy cable ties to simulate this, and I'm happy that a spacer/extra thick washer type thing will be the perfect thing to help stop this. For the linking mechanism I used some spare thick pieces of steel, and some spare braking components I had lying around. Plates welded to the shifter mechanism, and the gear stick, with holes drilled in them. Then a brake pedal clevis bolted on each side. I welded a brake master pushrod into the frontmost clevis, and have it threaded into the rear one, so I can adjust the gearstick position slightly if I want to. With washers between the clevises and their mounts, they both have some ability to pivot the link bar, so shifting doesn't have any excessive tension to it.  Apologies for the bad photo, but you get the idea. Little bit of spatter I need to clean up, but the welds seem strong enough. Made a quick video of how it works: I actually want to remove the shifter extension I have on the gear stick as I feel it isn't really needed now, plus that will help to shorten the throw a bit more. Overall pretty happy with it for a first attempt at something like this. It got me home on the 20 odd mile drive from the unit, so it can't be that bad 😂 I just want to add a few more welds to the box section plate on the inside, and add the spacer to the left of the rose joint, and probably strengthen the way the thread is mounted in the underside of the gearstick to prevent any issues. It's definitely a much better setup than before. 1st and 2nd shifts the rear part of the shifter is a little close to the handbrake, but it's manageable and doesn't make contact with it. |

|

|

|

Post by scottydugg on Aug 10, 2023 10:46:06 GMT

I knew all those hours watching YouTube builds would come in handy eventually! Looks a good solution so far, if the handbrakes in the way maybe it's time for a hydro  |

|

|

|

Post by dadbif on Aug 11, 2023 6:44:34 GMT

Looking good! The best solutions are always the ones you do yourself.

|

|

|

|

Post by Bilbo on Aug 14, 2023 8:03:53 GMT

I knew all those hours watching YouTube builds would come in handy eventually! Looks a good solution so far, if the handbrakes in the way maybe it's time for a hydro  Haha, many many hours of watching some very smart people build cars on there over the years! Oh god, I'm not sure the drums would like a hydro much hahaha. Looking good! The best solutions are always the ones you do yourself. Oh for sure, very satisfying making stuff yourself too! |

|

|

|

Post by Bilbo on Aug 14, 2023 8:35:28 GMT

So, the new shifter isn't bad, done a bit more to it to improve things and it seems fairly good now. I had an issue initially as the thread I welded into the base of the gear knob itself wasn't welded too well, and it snapped. So I drilled out the hole wider and have now filled all around the thread with weld, it seems a lot stronger than before and had no issues as of yet (touch wood). Also removed the extender and just wound the gear knob directly to the shifter, this has helped with the throw, it feels a bit nicer now that it is shorter. Had some adhesive backed sound deadening so cut it up and placed it all around the shifter. It's not 100% perfect, but it has helped a lot with heat and air rushing in from underneath, even with no carpet or centre console top/gaiter placed over it yet, so that's promising.  I am finding the gear shifts a little bit tight, which isn't ideal. The bolt and washer method allows pivot on the front and rear, but I think I'm going to change it up. I have to run a bolted method on the front, as it is on a rose joint if I added a loose fitting it would likely feel very loose and wobbly, but for the rear I'm thinking of changing out the nut and bolt for a clevis pin type fitting that will allow the same range of movement with a lot less resistance. Currently the shifts are just a bit too tight, and it is slowing down my ability to change gear quickly. Will test out using a clevis pin that will hold it in place but have very limited resistance, should work well hopefully. Other than that, the car is good, plenty more I want to get on with, but it's being a super daily at the moment. Other than a brief period of lean running on hot starts (afterstart enrichment/intake temp sensor heatsoak related I think), it just takes the miles no trouble. The map is improving each time I take it out, and it isn't far off OEM driveability at this point, which is great.  |

|

|

|

Post by scottydugg on Aug 14, 2023 15:45:03 GMT

I found you need to add after start enrichment for heat-soaked restarts, a fair bit actually to get it to start and not die, then some more to start and not try to die. Ideas for the shifter sound good as well.

|

|

|

|

Post by Bilbo on Aug 21, 2023 12:02:49 GMT

I found you need to add after start enrichment for heat-soaked restarts, a fair bit actually to get it to start and not die, then some more to start and not try to die. Ideas for the shifter sound good as well. Yeah this seems to be what it wants. It's an annoying one, it's not like my air temp is insane or anything on hot restarts, I need to look into what is causing it. I've seen some suggestions it could be related to the intake manifold itself, or something fuel rail related, but I'll have a look and see what I can do. |

|

|

|

Post by Bilbo on Aug 21, 2023 12:17:37 GMT

Right, so made a couple more changes to the shifter. The tightness was starting to annoy me a bit, so I did what I said before and changed the rear side to a clevis pin with retaining clip. It felt a little loose so I put a washer just before the retaining clip and now it's great. A lot easier to move the shifter back and forward, and the lateral movements are basically unaffected. It also likes to pop itself back to neutral in the centre a bit better than before, which is always good. The front bar for the rose joint was also annoying me. The little metal spacer to the left of the rose joint worked well, but mainly on overrun it made a nasty rattling noise, and the higher revs you were, the worse it was. So I have now changed both sides of the rose joint to a rubber spacer. I think the pieces I used were actually those little rubber cylinders that come on a throttle cable that you slot onto a bracket to secure the cable down with. But they work perfectly for this. They stop the rose joint moving about, they don't rattle, and they have some flex in them so the rose joint can pivot sideways exactly as needed. Ideal.  It's still hardly a professional looking product, but it works quite well and gear shifts are the best they've been so far in this car! The sound deadening stuff and carpet offcuts I have put in work quite well at preventing heat getting in, and there is no hot air from under the car getting in now, which is nice. Still need to sort out the mess of a cut up centre console, but it'll get there. Unrelated, but I am getting a rather horrible weird noise on overrun now. Sounds like it is clutch/release bearing related. No ill effects as of yet, but it's like a weird metal sound, almost sounds squelchy if that makes any sense 😂 First assumption was maybe the rear main had gone and was spitting oil onto everything in the bellhousing, but the weep hole is bone dry. This is actually the only MX-5 engined vehicle I've ever owned that drops zero fluids of any kind on the floor haha. I'll have a look into it, but I reckon it's inside the bellhousing annoyingly. I have noticed with this new shifter that there is a fair bit of wobble though, by which I mean the whole box is moving about more than I'd like, mainly when starting the car. When driving it isn't noticeable, but I have got my 40% stiffer IL Motorsport engine mounts still lying around from my mk1 5, so I may just fit those. Current ones are old original MX-5 ones that came with the engine from the donor. Might also have a look at replacing the bobbin bushes for the box mount for some kind of poly ones. Should make it all a bit tighter. |

|

|

|

Post by Bilbo on Aug 28, 2023 23:06:49 GMT

So got the car on the ramp this weekend, as a couple of new noises appeared. A metallic vibrating sound, this was actually the exhaust gently vibrating against the gearbox brace a little on overrun. Now sorted. The other noise I mentioned previously. After bolt checking everything, having a look over everything in the area, including the prop, nothing stands out as being the issue. So I think my initial thought that it is the clutch release bearing is correct. MX-5s are notorious for release bearing noise. Usually completely harmless, but really annoying. This has always had the classic noise, goes away when clutch is pressed. This noise is a bit more full on, the bearing sounds on its last legs, but it is what it is. It's either that or the flywheel spigot bearing, though noise from that is not something that I have ever encountered on a 5 box before. I have a 1.6 flywheel upstairs (lighter than the 1.8 one I have on), so when it comes to it I'll replace the clutch and flywheel with a 1.6 sized setup, still plenty good enough for the power I'm running, so no worries there. In other news I was getting a little tired of basically falling out of the standard seat on hard cornering. The seat rail setup on these are very strange, the standard rails are this awful hooked metal system on the rear, with a pivoting bar on the front. Never really liked it. I wanted to get a basic set of fixed rails in place for some different seats. I had a set of MX-5 side mount rails lying around, so decided to make them work. The left side of the floor is raised compared to the right, which complicates things, but these rails have multiple holes, so I've managed to use the lower holes on the left, and the top holes on the right:  Drilled some new holes. Top left of the photo was a pain as that section is boxed in, can't get to it from underneath. Took some messing about, but got it bolted up. The other 3 fixing points go through the floor with massive spreaders/washers on the underside, and brand new nyloc nuts to prevent any loosening. Washers on the bolt head side too to spread the load a little. These are then side mounted into the bucket seat, and the floor mounting points are long holes that allow side to side movement so the width can be adjusted for different seat types. Now in terms of seats, I have my rather tired torn Sparco Sprint that I took out of my 5 when I broke it for parts. The other option was an absolutely god awful OMP bucket seat I got for £20 a while ago. It has I believe a 1996 FIA tag on it 😂 It's a truly awful seat, I don't like it at all. So Sparco it is.   Ignore the tape on the scuttle vents, I've still not got round to sorting this permanently, but this keeps rain water out of the engine bay, which runs into the chassis rails. I don't want that, it's a stupid design, just asking for rust issues. So they're still sealed up with waterproof tape. Looks crap, but it does the job until I can be bothered to sort it properly.  Does it suit the car? No, not really. But, it was a really good drive being in a seat that actually holds you in place again. Cornering was much nicer as I'm not clinging to the big old OEM steering wheel for dear life haha. It is temporary, when funds allow I'd like to get some form of retro looking recliner type bucket seats. Nothing full race spec, something that looks sporty but still somewhat comfortable. Recaro recliners would be a great choice, but pricey. Maybe some old school Recaros if I can find some for a decent price. Would just get Manta ones, but to be honest I just dislike that OEM rail system and would prefer if I was going to have moving rails to have proper modern sliding rails, and it would be a shame to hack up some nice Manta seats to do that. We'll see, this will do for now, it is much more fun to drive. |

|

|

|

Post by scottydugg on Aug 29, 2023 8:47:14 GMT

Looking good, I think most of the retro buckets I looked at were bottom mount only, so that might have it's own issues.

|

|

|

|

Post by Bilbo on Aug 29, 2023 11:08:40 GMT

Looking good, I think most of the retro buckets I looked at were bottom mount only, so that might have it's own issues. Yeah I'll likely need to adapt the rail for a bottom mount seat in that case. I'll probably redo them with sliding rails tbh, I'd like to have some adjustment. |

|

|

|

Post by boggissimo on Aug 30, 2023 10:52:59 GMT

|

|