|

|

Post by browno on Apr 25, 2017 11:28:17 GMT

Hopefully got a while yet to get the mechanical bits sorted - I think I am looking at Mid-June... so need to keep the momentum up!

|

|

|

|

Post by browno on Apr 28, 2017 9:51:35 GMT

Time for another update, and some good news! Using a combination of 3 mechanical engineers, a 20 Tonne press, a blasting cabinet, a large impact gun and a big bar, we have managed to remove the lower wishbone long bolts and the n/s driveshaft...  8A1E2EC6-0872-4342-9B58-CF203B4D34D6_zpsip9n2dzj 8A1E2EC6-0872-4342-9B58-CF203B4D34D6_zpsip9n2dzj on Flickr There was, however a casualty in the fight - we (well, ok, I) got a bit keen to load up the press on the first bolt, and while it moved with a bang, we realised that the bang wasn't only down to the bolt moving...  2B50800A-CF96-43EF-89A4-87B0A42FB56C_zpstveko4qg 2B50800A-CF96-43EF-89A4-87B0A42FB56C_zpstveko4qg on Flickr So, I have ordered a replacement arm from Autolink, which wasn't too costly. One good note was that the bolts both came out good and straight and are reusable with a good clean-up (you can see where I tried to clean up the right-hand one in-situ with the soda blaster, which helped a little).  3BA26D31-8145-4099-9C43-9CF05BF06F53_zpsjruhylzo 3BA26D31-8145-4099-9C43-9CF05BF06F53_zpsjruhylzo on Flickr The next job was to work on removing the bushes, for which I first planned on making use of the press again - I tried one using sockets and threaded bar and just succeeded in devising a way to tension the threaded bar until it snapped! I then had a go on the press, and was a little worried about how much pressure was needed to push the bushes out, and that this might affect the integrity of the wishbones (I don't want to damage any more!), so I resorted to FIRE! I set myself up a workstation at the bottom of the garden and attacked the bushes with the blowtorch - which (after I had got a decent technique and replaced the gas canister!) was proving relatively quick at about 5 minutes per bush, and was quite satisfying!  FC53532A-5710-4DFF-A322-D5BF9470A465_zpstqoqhwha FC53532A-5710-4DFF-A322-D5BF9470A465_zpstqoqhwha on Flickr So I now have a good pile of wishbones without bushes that just need a bit of a cleanup of the last traces of rubber before I can take them off for powdercoating early next week (hopefully should get the replacement wishbone from Autolink today, so I can get that prepped too).  6A6B929D-EE1D-4C95-A08C-DC08BDC6DEBF_zpsc7bgpicw 6A6B929D-EE1D-4C95-A08C-DC08BDC6DEBF_zpsc7bgpicw on Flickr Hopefully I can also have a decent weekend - and pick up some more bits and bobs at the kitcar show on Sunday! |

|

|

|

Post by browno on May 3, 2017 22:25:53 GMT

So, update time again and more progress (and a trip to the kit car show too) Firstly, while waiting for my bits to arrive, I have got the engine mounted on the engine stand, and have started cleaning and painting some bits, starting with driveshafts, diff housing and engine block...  6C37449F-52AF-4EEA-87B2-169770DCF018_zpsk9vwnieg 6C37449F-52AF-4EEA-87B2-169770DCF018_zpsk9vwnieg on Flickr  7A68B931-CA8A-4C53-9DA4-DEF8251EE708_zpsjy7ebfxz 7A68B931-CA8A-4C53-9DA4-DEF8251EE708_zpsjy7ebfxz on Flickr  F27E9249-4821-443D-93E0-9AA05A6DBB74_zpsu60hhkzz F27E9249-4821-443D-93E0-9AA05A6DBB74_zpsu60hhkzz on Flickr  29FDBD70-C03F-43F0-8ECD-DDC620694840_zps0ekmevl9 29FDBD70-C03F-43F0-8ECD-DDC620694840_zps0ekmevl9 on Flickr  9C1DBBEB-253F-47D1-9067-00CB9761900E_zpsq1kkvfmt 9C1DBBEB-253F-47D1-9067-00CB9761900E_zpsq1kkvfmt on Flickr I have also been getting the last bits of pre-powder coat prep done, including trimming the edges of the front subframe to prevent interference with springs (as recommended by Stuart when I visited MEV) - I have chopped back so the edge is now 15mm from the outer edge of the bolt holes.  B862FCBA-B2B5-448C-BAD2-1BFA8B70851B_zpsserroloh B862FCBA-B2B5-448C-BAD2-1BFA8B70851B_zpsserroloh on Flickr and also trimmed the rear U-brace to remove the extraneous end sections  DD99206F-DD2E-401C-BBED-031A62626523_zpseqhp5tqp DD99206F-DD2E-401C-BBED-031A62626523_zpseqhp5tqp on Flickr I had a good trip to Stoneleigh on Sunday where I had a good look over all the various cars there, and a chat to a few folks about my build. I did get a bit of a kick to get moving when I went to the MEV stand and Julie told me that my chassis is built and powder coated (and apparently looking very good!) and they are now getting the bodywork made up - so it will be ready imminently! Today I have been able to make some more progress, as I had still be waiting for my bits from Autolink and had thought that they were delayed due to the bank holiday - and thankfully checked the tracking, which told me that (despite no card being left at my home), the parcel had been taken to the post office in the next village. At least that meant that I could fetch that and now have my final wishbone - so tonight whipped out the bushes from that and have got all my bits ready to drop in for powder coating in the morning, which will be a good step in the right direction. I also had a second parcel today, in the form of my Energy Suspension bush set - which looks very good, but also makes me think I've still got plenty of work to do to get all of them fitted!  B8240572-A9CD-42A7-86EC-EE5887672582_zpsenumwsle B8240572-A9CD-42A7-86EC-EE5887672582_zpsenumwsle on Flickr |

|

|

|

Post by myothercarsa2cv on May 10, 2017 11:28:53 GMT

Enjoying the build! Considering going back to a kit car soon myself... I'm getting the itch to build something...

|

|

|

|

Post by browno on May 15, 2017 9:44:56 GMT

So, a bit more progress again, so time for another update... Firstly, I painted up the manifold heatshield and remounted to the block (replacing a downpipe stud that snapped during removal in the process)  30363948-75BD-40A4-AD90-5CE616ADDA9A_zpspeeppuj2 30363948-75BD-40A4-AD90-5CE616ADDA9A_zpspeeppuj2 on Flickr and started cleaning up my front upper wishbones with rust converter followed by hammerite (I hadn't sent these for blasting and coating due to the upper balljoints), and also my rear hubs.  4710308A-C38D-4D04-81ED-1DF494C95DC4_zpsrzirtgkh 4710308A-C38D-4D04-81ED-1DF494C95DC4_zpsrzirtgkh on Flickr  5B10D8B9-56CF-4C02-8020-C98C5CC5A6A9_zpsmbvxtjrj 5B10D8B9-56CF-4C02-8020-C98C5CC5A6A9_zpsmbvxtjrj on Flickr and also picked up a bit pile of now shiny bits from powder coating - which look completely transformed!  C12E4861-0B47-44EB-9F8A-395ADBF4C939_zpsbl6vvn0b C12E4861-0B47-44EB-9F8A-395ADBF4C939_zpsbl6vvn0b on Flickr I'm happy with the job they've done at even ensuring that the insides of some of the open sections on the wishbones and subframes are well coated too.  86A7212A-C665-49DE-93C8-65E60D5805C3_zpskwuyiybp 86A7212A-C665-49DE-93C8-65E60D5805C3_zpskwuyiybp on Flickr I also started cleaning up some of my nuts and bolts - and to do this, after looking around I used "frost rust remover" which was £25 for 5 litres and is said to remove the rust without the use of acids or alkalis (being an inorganic chemist, this will be using selective chelation of the iron oxide - essentially pulling the rust into solution). So far, I am impressed by the results - essentially leave the parts in the solution overnight and then give them a rinse off and a clean with a wire brush and it has a pretty decent effect (this is a very good one - others have needed a second dunk in the solution).  C1BACD93-C793-4621-8EC3-9A7E8E77855D_zpsjxbdulso C1BACD93-C793-4621-8EC3-9A7E8E77855D_zpsjxbdulso on Flickr  3F74FA3F-E6C0-4B74-B7AE-A09C4C2893AB_zpskhrpyfbn 3F74FA3F-E6C0-4B74-B7AE-A09C4C2893AB_zpskhrpyfbn on Flickr I have started mounting the diff into the subframe, ready to begin making the pile of parts back into something more like a powertrain, and have given the garage a good clean out, as I am now hopefully finished with having flaky rust and dust everywhere, and can start building in a cleaner environment! Once all was clean, I have then laid out the bits in preparation for a rebuilding session!  B631132C-EA0B-43F9-8617-709F766A352F_zpsfdbkhbte B631132C-EA0B-43F9-8617-709F766A352F_zpsfdbkhbte on Flickr  59E293AD-B989-411C-B8CE-33E3C37A89D3_zps6j48so1l 59E293AD-B989-411C-B8CE-33E3C37A89D3_zps6j48so1l on Flickr So, it feels like I am making progress and finally turning the corner from stripping down and dealing with mucky nasty parts into actually being able to start building something that will look nice and clean - hopefully the next update will continue that trend! |

|

|

|

Post by browno on May 18, 2017 13:47:07 GMT

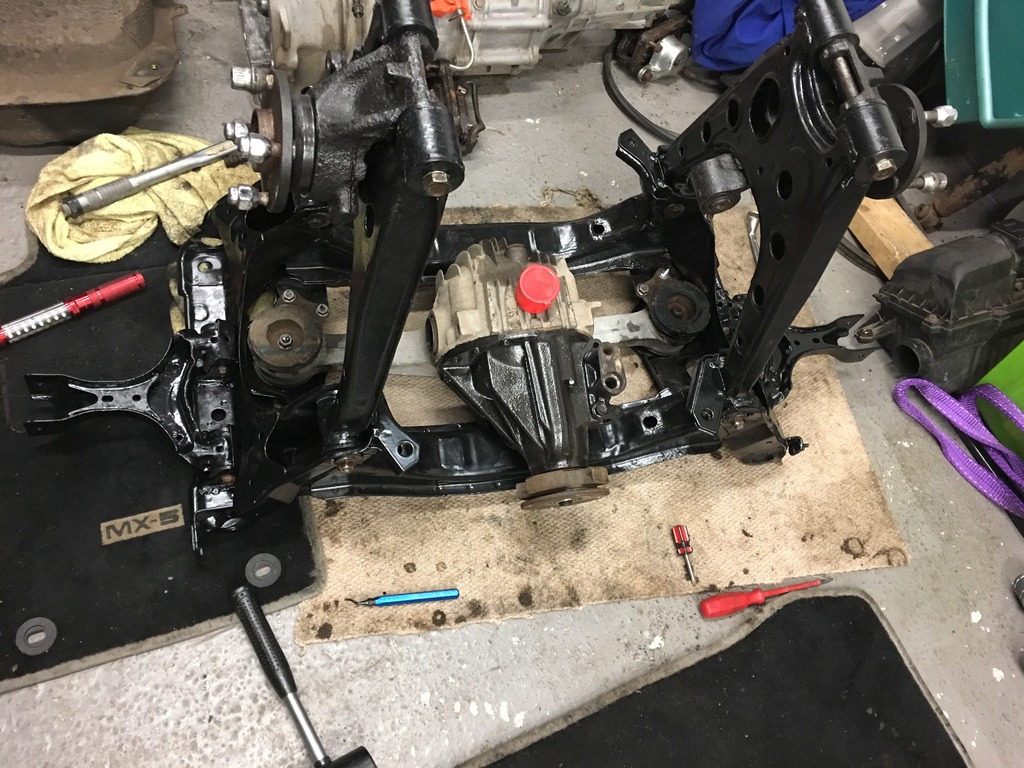

So since the last update I have been cracking on with assembly - and getting sticky polybush grease over everything I touch! First I started on the back-end and got everything together (although I initially put the hubs on the wrong sides, as I had turned the subframe around while assembling!)  C8FED11C-0B97-4B4B-A3FB-7B8A921ACFCC_zpstlniiil4 C8FED11C-0B97-4B4B-A3FB-7B8A921ACFCC_zpstlniiil4 on Flickr I haven't yet got the driveshafts located into the diff - they are not locating by simply pushing them in, and I didn't want to get too aggressive with them - will have another go tonight. I guess it is just a case of getting the spring clips to pop into place - I can feel that the splines are lined up, so it is just that last push I think.  CC0BBBA1-2141-40CB-9653-2F341A676416_zpsmnevkmi5 CC0BBBA1-2141-40CB-9653-2F341A676416_zpsmnevkmi5 on Flickr next, I decided to mount the front subframe to the engine while it was on the stand, and got one pair of wishbones fitted  49210ABB-D209-4E10-9E29-44E7FE6DA5A0_zpsvmsst77d 49210ABB-D209-4E10-9E29-44E7FE6DA5A0_zpsvmsst77d on Flickr following which I then dropped the assembly onto axle stands to allow me to fit the new clutch - this was a step that I had wondered about, as the clutch was not too worn (but is on 74k) - and I am thinking that FI might eventually be on the cards, but having won some money in our monthly tote at work, I thought I'd get an Exedy clutch kit sorted and put it in while I had everything apart.  3C2F3E18-70D2-46EE-9EB0-37F6E7B1B956_zpsxpzktsjn 3C2F3E18-70D2-46EE-9EB0-37F6E7B1B956_zpsxpzktsjn on Flickr So with that done, I could reattach the gearbox - which I haven't painted - since it is bare alloy, I figure is isn't going to corrode, and isn't on display, so I've simply given it a good clean and will put some decent new fluid in it (as it is my job to develop gearbox oils, I am going to make sure of that!). I have also rebuilt the other wishbones too, so I am starting to pull together the powertrain. You will notice that the top end of the engine hasn't been played with yet - I am going to paint/coat the cam cover and change the gasket and CAS o-ring, but figured I can do that at any stage in the build.  02C40877-53FD-4D34-94A4-DE090750F39F_zps0slhrj6w 02C40877-53FD-4D34-94A4-DE090750F39F_zps0slhrj6w on Flickr I have a few more jobs to do tonight, which include fitting up the front hubs (with new upper balljoint boots and one lower balljoint where I had to chop out a stuck bolt), swapping in the new clutch slave cylinder, fitting the rear driveshafts and hubs and then trying to get the PPF and propshaft installed so that I have a complete powertrain! (obviously I then need to add brakes - but they are also ready with new discs, pads and calipers all round to go on). |

|

|

|

Post by browno on Jun 5, 2017 22:24:04 GMT

So, it has been a couple of weeks since the last update and I have a little more progress to report. Firstly, continuing from the last update, I got the driveshafts popped into place properly, and then started to reunite both ends.  IMG_4949_zpsj3d5jg7z IMG_4949_zpsj3d5jg7z on Flickr  IMG_4951_zpszw4ij2ah IMG_4951_zpszw4ij2ah on Flickr Then I fitted up the new slave cylinder and pipework.  IMG_4956_zps7gxzjsbg IMG_4956_zps7gxzjsbg on Flickr I also replaced the bottom ballpoint that I had had to chop out and so could put the front hubs in place (not torqued or finished in this pic).  IMG_4957_zps7fj17wfr IMG_4957_zps7fj17wfr on Flickr And tonight (after a week's holiday) I have been depowering my steering - getting rid of the seals from the rack by carefully cutting it away.  7DB4E3B4-239C-4103-BAF9-0F191E0405A9_zps3zbgjf5c 7DB4E3B4-239C-4103-BAF9-0F191E0405A9_zps3zbgjf5c on Flickr and all rebuilt (but needing a clean off before refitting)...  1BD853E9-3917-4740-A13E-0DAAB9804D1A_zpsyem4qykk 1BD853E9-3917-4740-A13E-0DAAB9804D1A_zpsyem4qykk on Flickr Now I need to get cracking as I have been in touch with MEV and my kit is ready - so I will hopefully be getting a van sorted to go and get the missing bit of the equation sorted out very soon - I just need to shift my Mini out of the garage temporarily so that I will have space to do the floors and pipework prior to fitting the chassis to the rollerskate. |

|

|

|

Post by browno on Jun 10, 2017 11:00:40 GMT

Another update today, and it is a big milestone! Firstly, I have been getting a series of little jobs on the mechanicals to get them sorted, and ordered (and quickly received) my suspension. I debated a lot about what to use on the Exocet - whtether to upgrade later or to go straight to coilovers. I have been very happy with the Meister R's that I have on my mk3 - and had thought to go for another set, but I have ended up with a set of Gaz gold pros - as many Exocets seem to use them, and to try something different. So they are ready to be fitted, along with a set of silicone hoses en-route from fast5 to sort the cooling system.  B670F95B-142C-4EDF-825C-77398BEBF8ED_zpschpwungf B670F95B-142C-4EDF-825C-77398BEBF8ED_zpschpwungf on Flickr Then, the big event - having seen Stuart and MEV getting a bit of coverage on the local news the other night - with my kit clearly visible in the background, I was keen to see it in the metal! I was pleased to head out of work early yesterday to pick up a van and head up to Mansfield, where I could pick up my kit. As you will see, I have decided that the car deserved a striking colour scheme - I was originally planning contrasting body and chassis as many (most) builders go for - but after deliberating and playing with photoshop, decided that a single colour would be good and allow me to have the option to add some vinyl to break it up later if it is too much!  F7075B51-7E7C-4E6A-B61D-57A4F0641BDC_zpsagdvhjzr F7075B51-7E7C-4E6A-B61D-57A4F0641BDC_zpsagdvhjzr on Flickr We were upgraded to a jumbo transit - which was enormous, and so we had no worries about space!  F4858408-13CD-46B4-8D60-4AB8FC10F334_zpshnuptamj F4858408-13CD-46B4-8D60-4AB8FC10F334_zpshnuptamj on Flickr I had taken a trip to screwfix and bought a load of 28mm pipe lagging to make sure I could protect the powder coat - and so got plenty of that on to prevent chips - and after a short drive, we could lift it into the garage...  AB5CB4E2-8FDE-49CC-8825-840597809E17_zpscv1grxls AB5CB4E2-8FDE-49CC-8825-840597809E17_zpscv1grxls on Flickr And then set up the inevitable picture with the panels...  F9D84387-8040-4121-8811-C596D7DA68B4_zps7y9fgu2l F9D84387-8040-4121-8811-C596D7DA68B4_zps7y9fgu2l on Flickr  C9C3BFA8-B01D-49C2-B0D1-62D85B4C8AFE_zpsxyaxujgi C9C3BFA8-B01D-49C2-B0D1-62D85B4C8AFE_zpsxyaxujgi on Flickr So - thoughts so far are that I am liking the colour (which is a good start!) and I am liking the styling tweaks that have been done - the flat roll hoop is a big one, but also the new rear cover with the flat-top and areas mounded in for fog/reverse lights tidies up the rear end nicely. Overall, I am a happy customer - now to keep the momentum up and get ready to reunite shell and skate! |

|

oli

Chats A Bit

Posts: 184

|

Post by oli on Jun 11, 2017 14:03:03 GMT

Yes love the colour!!!

Hurry up and get it bolted together before winter comes back around..

|

|

|

|

Post by browno on Jun 18, 2017 21:40:08 GMT

Time for another progress update. First job was to whip off the front hubs and remove the remains of the brake heat shields. Of course, the bolts weren't too happy to be removed, so four of six snapped (despite me carefully trying to work them out!), so it was out with the drill and taps to provide a thread for the next stage - fitting the front wing stays temporarily (I have removed them again until after the body is on, so that I don't damage them in the meantime). As I was looking at the front-end and torquing things up, I discovered that both front upper balljoints have dodgy threads which don't want to tighten up. As a result I ordered a pair of new ones - by searching eBay for MOOG K500210, which I found is the part number for the replacements with built in grease-nipples, I got a pair for £50 posted inc. customs charges - a fair bit cheaper than the £35 each + post from the UK. They should hopefully be here later this week to install using the press at work.  6463D30C-BCEC-4BC6-882A-8F484B999CE9_zps6dzujmdt 6463D30C-BCEC-4BC6-882A-8F484B999CE9_zps6dzujmdt on Flickr  4EBF5B4D-2401-49A0-A69E-D96314681EEF_zpsidd2p1tp 4EBF5B4D-2401-49A0-A69E-D96314681EEF_zpsidd2p1tp on Flickr I then finished off fitting the bushes to the ARB drop links now that I have some more grease for the polybushes - I have left off the front ARB until I have the shell on and can bolt it into place.  64311FBC-3F5C-422A-8284-7400F3D8B06D_zpsapviiagj 64311FBC-3F5C-422A-8284-7400F3D8B06D_zpsapviiagj on Flickr I also rebuilt the rear brakes with new discs and pads and had a look if the lovely green HEL lines that I have acquired from a race-prepped Evo might do the honours - and I think that they will route nicely along the tunnel to meet a hard line along the way (they will be properly secured, I have just used a few cable ties to hold them in place for now).  B09D22FC-7D6C-4AF1-8DB5-56B2BBBC56D8_zpschajkzcq B09D22FC-7D6C-4AF1-8DB5-56B2BBBC56D8_zpschajkzcq on Flickr I then fitted my silicone hose set from Dan at Fast 5 - which are very nice, and should keep things water-tight once it is all up and running - even coming with a full set of replacement hose clamps.  CC58BAC9-7798-4960-8095-57B4333C7D60_zps1uolbxbv CC58BAC9-7798-4960-8095-57B4333C7D60_zps1uolbxbv on Flickr I also tidied up the strut tops (seen here in primer), and have fitted them to my coilovers.  44E78D9E-BA4F-413E-A6D7-EAF36C784008_zpslg7kq4wp 44E78D9E-BA4F-413E-A6D7-EAF36C784008_zpslg7kq4wp on Flickr and finally, I have suspended the bonnet panel from the roof to keep it out of harm's way while I get busy preparing the floors and pipework into the shell, which is the project for the start of this week.  D6B180BE-ECC7-4A4A-BDA0-4590FD600E38_zpsxta6cnrt D6B180BE-ECC7-4A4A-BDA0-4590FD600E38_zpsxta6cnrt on Flickr |

|

|

|

Post by browno on Jun 19, 2017 21:57:28 GMT

|

|

|

|

Post by Horney on Jun 20, 2017 6:46:34 GMT

Coming along nicely!

|

|

|

|

Post by browno on Jun 26, 2017 22:34:02 GMT

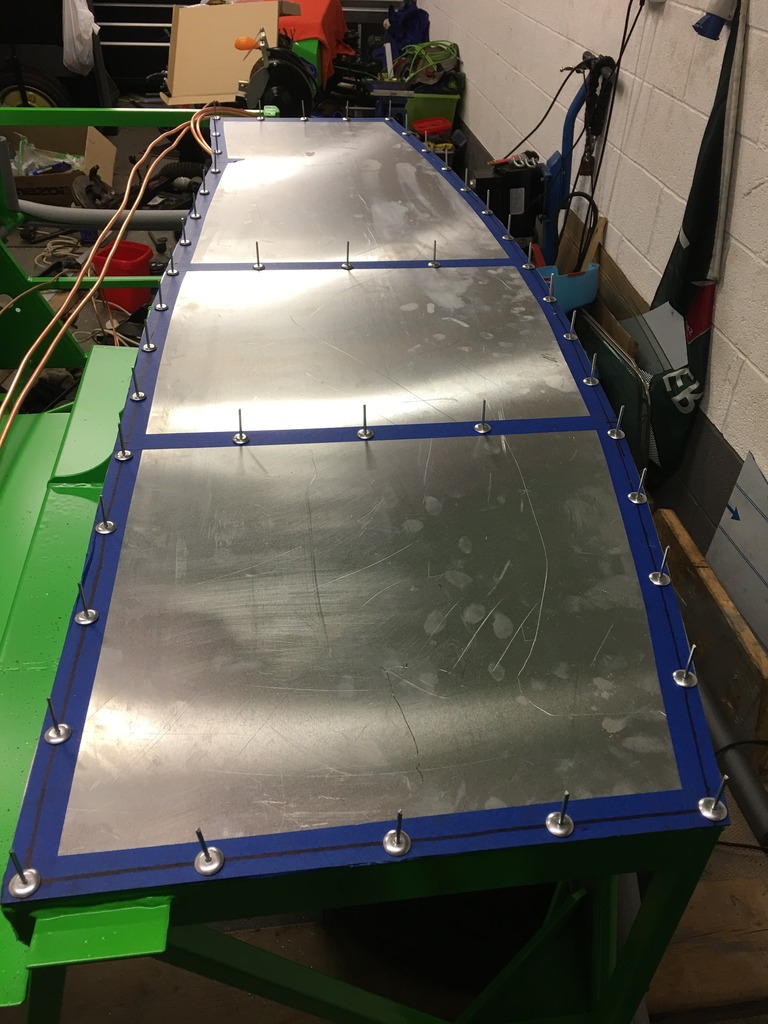

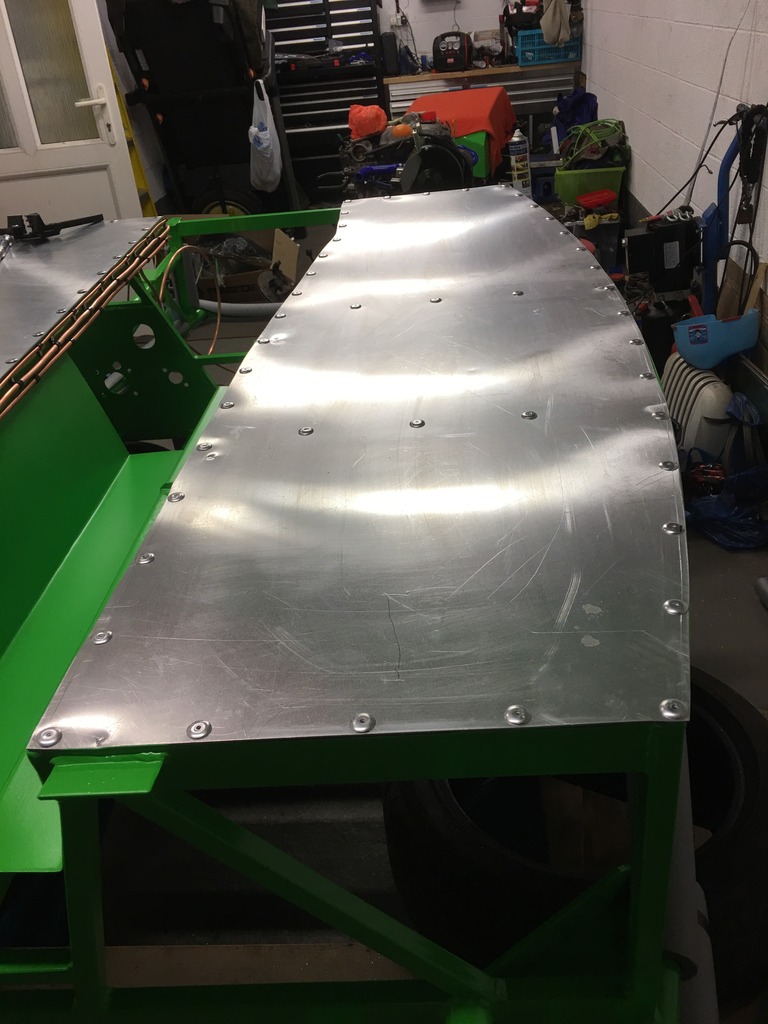

Thanks again for the encouragement, Horney! Time for another instalment in my build, and more progress along the road to having something car-shaped rather than a pile of bits in the garage! So the first job from last time was to get started prepping the floor panels for fitting - so firstly I masked up the edges, then with the panels clamped in position, marked out a 10mm line from the edge right round (the tubing is 20mm, so that will get me central). Then I evenly spaced my holes at approx 100mm centres (variation depending on dividing up the spaces evenly and logically!), and then centre punched and first drilled the panels and deburred before remounting and spotting through to drill the chassis rails.  B569DF52-55B2-4D84-85DB-64B08D5F8896_zpsxph9avc3 B569DF52-55B2-4D84-85DB-64B08D5F8896_zpsxph9avc3 on Flickr  B831A6D9-D5C7-4703-BAFE-BF677C625978_zpsablebxxb B831A6D9-D5C7-4703-BAFE-BF677C625978_zpsablebxxb on Flickr Then I also laid out the hard lines for fuel flow and return and also rear brakes, and after mocking up on a bit of scrap ali, started drilling and fixing the lines with p-clips at 150mm spacing (slight overkill compared to the 200mm recommended by many, but again it fitted nicely into the available space). I have made sure to leave plenty of pipe each end for now to be relatively free with routing of the ends...  DE20D261-8B90-4B65-85D2-563A1103C82F_zpscielzgra DE20D261-8B90-4B65-85D2-563A1103C82F_zpscielzgra on Flickr  744A0698-BAE6-4852-9473-0D7F61B3E069_zpstlwpvcg8 744A0698-BAE6-4852-9473-0D7F61B3E069_zpstlwpvcg8 on Flickr Then today, I had a great help from a colleague (and former vinyl sign maker) to wrap the floors - with the edges left clear to allow some space for a good bead of tiger seal to ensure the ali is gripped and sealed properly.  9F928DD9-1C54-4996-9937-F1A95045FF75_zps6toxoksv 9F928DD9-1C54-4996-9937-F1A95045FF75_zps6toxoksv on Flickr Then I applied a thin bead of tiger seal all around the mating surfaces - thinking that less is more here certainly turned out right - I had a little oozing, but only very slight, and which was easily cleaned up with a solvent-soaked rag.  5E5EAE1F-E97D-4A9D-90D7-AFBBAAF7FA06_zpsgdh891eg 5E5EAE1F-E97D-4A9D-90D7-AFBBAAF7FA06_zpsgdh891eg on Flickr Then having got busy with the lazy-tongs (the cheap silverline ones that I bought having had issues during the line fitting, I used my mate's Clarke ones, which had it all,done super quickly), and I have fitted floors...  1D5247C9-9971-40E0-A807-97F10391E3D6_zpsyfsiaauh 1D5247C9-9971-40E0-A807-97F10391E3D6_zpsyfsiaauh on Flickr  98DE7551-9D3A-4957-A372-541F61E40226_zpsh5its87m 98DE7551-9D3A-4957-A372-541F61E40226_zpsh5its87m on Flickr And having debated what to do, I am pleased with how the carbon vinyl works to give a contrast against the green (even with the body still upside-down!)  2A8509D2-8118-4F26-9B86-38AEF9C059C2_zpsipqijqmi 2A8509D2-8118-4F26-9B86-38AEF9C059C2_zpsipqijqmi on Flickr So, I have front upper ball joints to change over tomorrow, and the upper arms to refit, and then it should hopefully be body-on time this week! Exciting times! |

|

|

|

Post by myothercarsa2cv on Jun 27, 2017 6:06:37 GMT

That looks super nice  A tip from my Caterham days - aluminium and steel react and corrode when in contact, so do everything you can to prevent that - I assume you're using steel rivets so it's worth painting the aluminium as well once it's drilled just to give you a little bit of extra protection. |

|

|

|

Post by browno on Jul 4, 2017 13:43:30 GMT

Hello again all - so, thanks to Photobucket, my thread (and all other forums!) has been butchered and none of the images are now showing which is a massive pain - but for now I have rehosted everything onto Flickr - HERESo, onto progress, and I have made some! First job was to flip the chassis over and turn it round the right way - and I could admire my floors properly...  9500EF38-9CE6-47C9-8284-F5FEA2865E6E_zpse5kafsex 9500EF38-9CE6-47C9-8284-F5FEA2865E6E_zpse5kafsex by Gaz Brown, on Flickr Then we lifted the body carefully through the garage and into position, which was pretty straighforward and everything lined up as it should...  8A809374-EF30-49A8-A216-DAB43E31526A_zps880fcpqo 8A809374-EF30-49A8-A216-DAB43E31526A_zps880fcpqo by Gaz Brown, on Flickr Then I could build up the rear suspension:  050066AF-BDEE-44CD-A6F8-6646E4CD3420_zpspo0fgroi 050066AF-BDEE-44CD-A6F8-6646E4CD3420_zpspo0fgroi by Gaz Brown, on Flickr and bolt down the chassis - with one minor schoolboy error when I tightened up this bolt with a ratchet spanner and then realised it was trapped (and of course wouldn't allow me to undo the bolt!) - which was easily solved by wedging a pry-bar in the gap to hold the nut!  17FBEC1A-E840-4E08-BBFD-C880EFE2598E_zps0nnhnajs 17FBEC1A-E840-4E08-BBFD-C880EFE2598E_zps0nnhnajs by Gaz Brown, on Flickr Next, I replaced both front upper balljoints and that also allowed me to build the front suspension up and fit the cycle wings so that I could torque up the front hubs.  C8E34086-06A9-4878-8251-C9A91B9EB58D_zps26rn92uy C8E34086-06A9-4878-8251-C9A91B9EB58D_zps26rn92uy by Gaz Brown, on Flickr and then I gave my pedal assemblies and steering column a lick of paint to tidy them and started having a go at fitting them. Once I had a feel for what I needed to do re: spacers (I chopped them off the brake pedal and put them on the servo side), and also had removed the stud from the clutch pedal and replaced with a longer nut & bolt, it looked like everything was lining up and the column fitted well with the help of some cable-ties...  Untitled Untitled by Gaz Brown, on Flickr  Untitled Untitled by Gaz Brown, on Flickr However, the steering column was only just touching the end of the rack fitting:  Untitled Untitled by Gaz Brown, on Flickr Having looked online I found reference to this in a few places including the exomotive build guide - exomotive.com/exocet/build-guide/pedals-steering/ which shows that you can extend the lower portion of the column easily... So, having successfully fitted an windscreen to my mate's Tiger kit, we were on a roll and so decided to tackle the column last night. I don't know if there is a difference in LHD and RHD columns (or differences by years) but this didn't work... looking at the lower shaft, we thought it had sealant round the splines - which turned out to be weld... but we persevered anyway, and starting filing away the weld - which revealed the ends of the splines.  Untitled Untitled by Gaz Brown, on Flickr  Untitled Untitled by Gaz Brown, on Flickr but once we had the weld clear, we discovered that the splines were only really long enough to locate the shaft for welding...  Untitled Untitled by Gaz Brown, on Flickr So now, I am going to be buying a replacement column - and having checked a mate's (also a '98 NA) that has the same shaft as mine - should I be looking to extend from the top half of the column, or are there different designs of column out there that have the extendable bottom section (or is this something that was only on LHD cars?)... At the very least - this might act as a reference for others that might come across the same problem not to get chop-happy!) - within minutes of posting my update on the MEV forum, I had an email from Stuart at MEV with the following information:  column column by Gaz Brown, on Flickr You wouldn't get that level of rapid support from many places! Now that I have seen Stuart's picture, I can see what he has done - effectively shortened the upper half of the outer - meaning that the lower portion will then fit properly. I will try this tonight on my upper column - and I now have a new lower on order, so can hopefully bolt that in once it arrives. I am still intrigued by the US approach though - this certainly suggests a significant difference in the columns across the pond (or all LHD)... So the saga will continue on this one shortly - but for now, I am really happy to be making good progress - I also now have tyres sorted and being fitted to the wheels at the moment - and have my spacers on order from Freaky Parts too... |

|