|

|

Post by browno on Jul 17, 2017 22:09:46 GMT

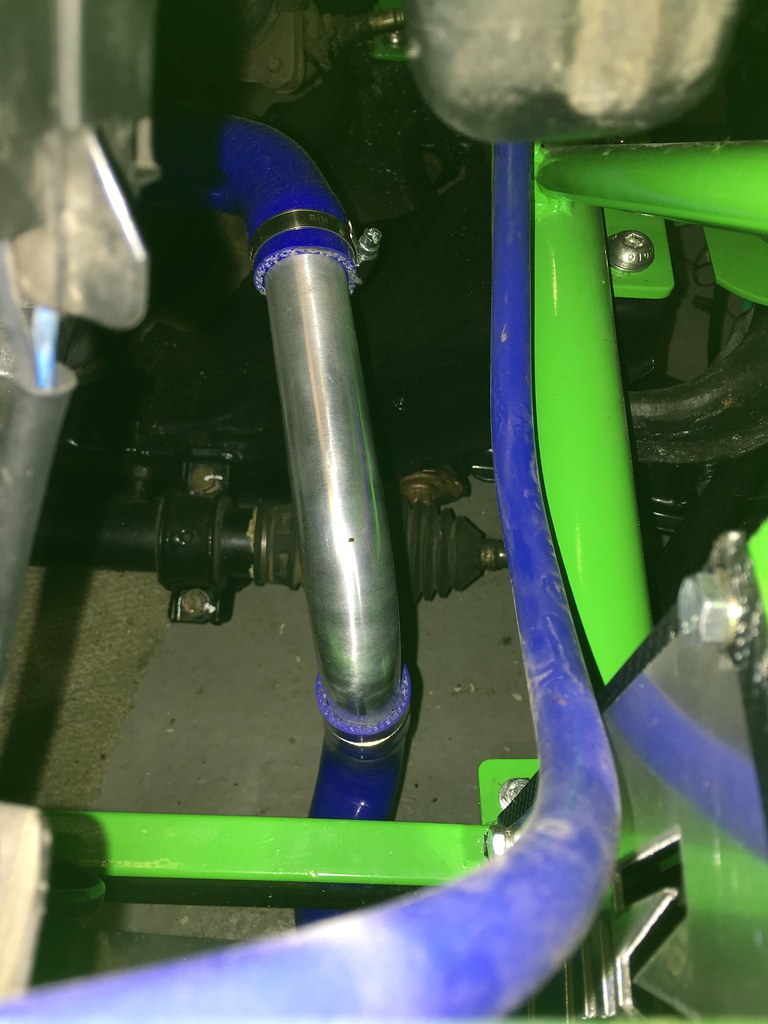

It's been a little while, but it is time for another progress update! I have managed to sort my column issues - following Stuart's instructions, I managed to bash away at my column and gain that vital extra inch!  Untitled Untitled by brownotribbs, on Flickr Which then allowed me to fit up my column properly... and connect up the (replacement) lower shaft...  Untitled Untitled by brownotribbs, on Flickr  Untitled Untitled by brownotribbs, on Flickr I have then been working to try and begin sorting details - so have the accelerator cable attached, handbrake cables installed and ready to bolt into place and also the clutch plumbed in and bled up, so that is now working. I have also chopped the front end of the fuel hard pipes and have fitted flexible hoses up to the fuel rail (although I have dropped one of the fuel-rail spacers, so will need to sort a replacement if it doesn't turn up on the floor!).  Untitled Untitled by brownotribbs, on Flickr I also got my new tyres (Federal RSRs, which I have been very pleased with on my mk3) fitted onto my new wheels and have trial fitted them in advance of my spacers arriving. Although I am not a big fan of black wheels in general, I think that they are the right choice to provide a good contrast to the green chassis and bodywork...  Untitled Untitled by brownotribbs, on Flickr And tonight (as I am waiting for my braided hoses to be modified for the brakes, so am holding off on piping them up), I started on the big box of spaghetti otherwise known as the loom!  Untitled Untitled by brownotribbs, on Flickr Thankfully, my labels appear to be all intact and legible so far, and I have started lying it all into place as a starting point - which means everything looks a little messy! Thankfully everything that I have come across so far has plugged into the right places, and the other connectors all seem to make sense (I predict this being a statement that might come back to haunt me!)  Untitled Untitled by brownotribbs, on Flickr  Untitled Untitled by brownotribbs, on Flickr So, it is all coming together - I need to bolt in the handbrake, sort the brake pipes and also the rear fuel pipe connections, but then it should be time to get it started and moving! |

|

|

|

Post by browno on Aug 15, 2017 10:04:54 GMT

I have progress again (I think I missed an update on here too - so apologies, now catching up!) - I have managed to get the fuel lines all in place (but not yet fixed until the tank is fully fitted), and have been finding places to ensure that all earths are grounded (albeit temporarily - a mixture of clamps either holding wires together, or holding them onto the block/ppf was functional if not pretty...). Having done that, I then jumped the fuel pump and primed the system, and was pleasantly surprised when I tried to turn the engine over... I only ran very briefly as I have no radiator installed at the moment (a new one is on the way) - but this is another good step forwards... Since firing it up, I have been making a little more progress, slightly steady though as I have been on holiday and also had to replace the brake master cylinder on my mk3 (it was leaking between the master and the servo). The day before my holidays I received a package from Freaky Parts containing my wheel spacers, which was good (but I was told in no uncertain terms that they would have to wait until I got home!). They look very nicely machined, and also are not quite as weighty as I thought they might be. So, over the weekend, I fitted the spacers and made sure that all studs were firmly thread-locked into place, at which point, I could then fit all four wheels properly.  Untitled Untitled on Flickr which meant that I could remove the axle-stands and drop the car onto its wheels for the first time! It definitely looks a lot lower than the MX-5 did, but I guess that's part of the point!  Untitled Untitled on Flickr Then last night I had a bit of time to do some more jobs, and was ably assisted by a friend from work (who has worked building some lovely race cars), and he had also modified my final brake flexi- lines. So first job was to loosely put them into place - with the rears run to the t-piece (now centrally located - will be bolted in place when my rivnut tool arrives!). we also did the fronts, but I didn't take any pics (and need to make up some brackets to hold them in an IVA-compliant position). I do then need to p-clip the flexis in place - but need to wait for a set of new banjo bolts to arrive so that I can get the routing perfected.  Untitled Untitled on Flickr We also removed the loom from the car - as I think I was maybe trying to run before I could walk - and needed the space to be able to fit the bulkhead panels and wiring tray. At least I know it runs, and could mark up all of the connectors that were required to make the car fire! The final job was then to fit up the handbrake lever and get that adjusted up - which worked ok after a bit of double checking t hat everything lined up properly. The good news being that once we had adjusted the new calipers and the cable, that I have the beginnings of some working brakes!  Untitled Untitled on Flickr So my plan of action now is to get the brake piping/hoses finished and secured then bleed them out, secure the handbrake cables and then start work on getting the bulkhead panels trimmed and fitted up before then fitting and modifying the loom. Oh, and my new (standard) radiator has also arrived, so I have fitted the MEV brackets to it, so I can install that too when I have my rivnut tool. |

|

|

|

Post by browno on Sept 6, 2017 21:37:58 GMT

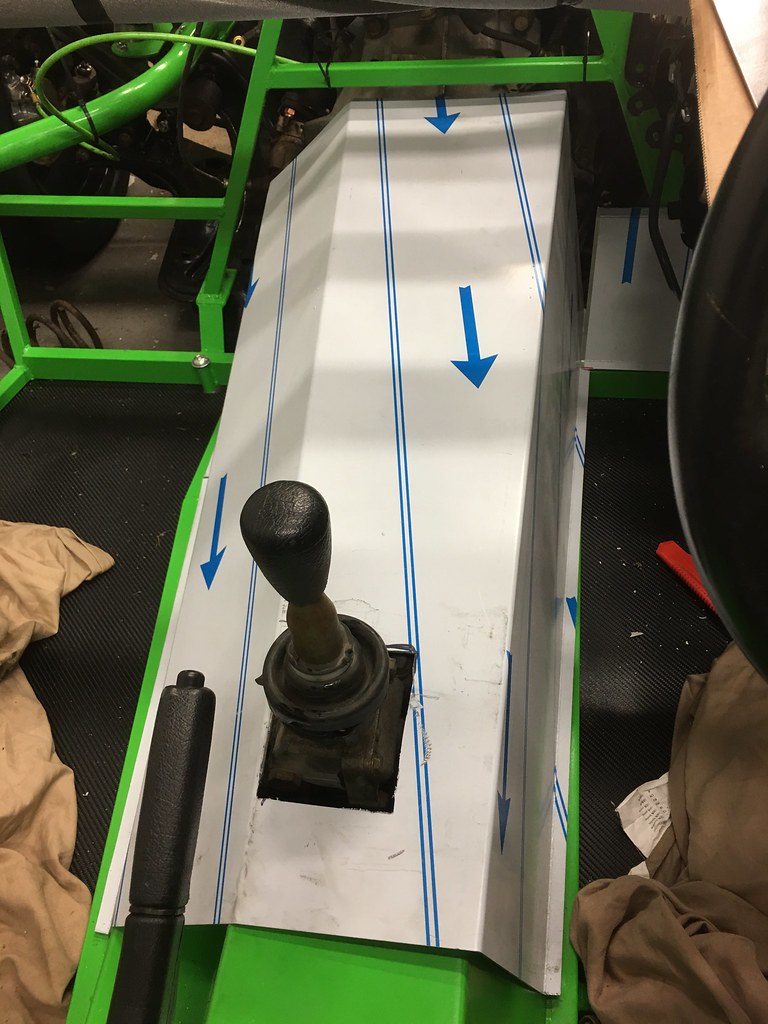

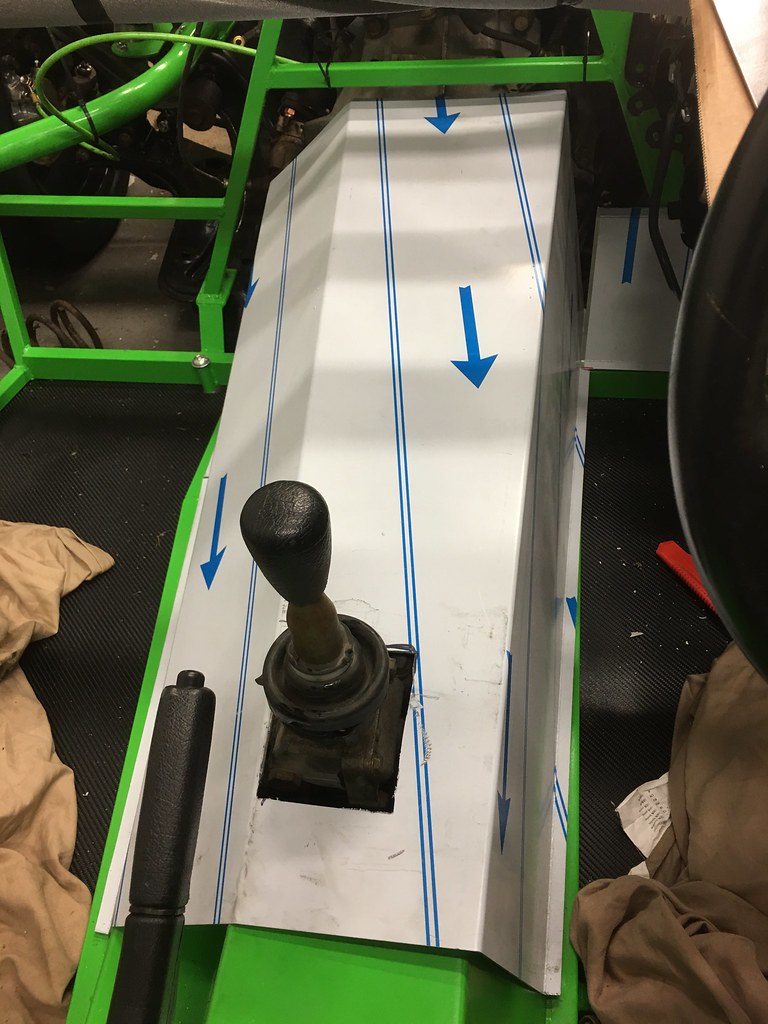

I have not been doing as much as I would have liked over the last couple of weeks, but have got a few bits done (I have also been getting my mini prepped for a rolling road setup, which has involved swapping carbs over and tweaking some bits). Firstly, having bought a rivnut tool, I fitted the radiator, which looks good - with them trimmed in carbon vinyl, whichI think works well (although we will see how it lasts once it has got hot):  Radiator fitted Radiator fitted on Flickr  Radiator fitted Radiator fitted on Flickr and next I have been working on figuring out the 3-D puzzle that is the tunnel and bulkhead panelling! This is where the loss of history from photo bucket has really hurt, as many of the threads I looked at on here and elsewhere had great descriptions, but no pictures to be able to really visualise what was going on. I began with trying to sketch out templates for the panels that need modifying/making. having started that, I then realised that I really needed to cut the hole for the gearstick and get the tunnel in place and the front end trimmed up before I finalise my templates. So tonights job was to do just that - and some measuring, double checking and marking was followed by a first conservative cut that was then gradually opened out to fit.  Untitled Untitled on Flickr This then allowed me to put my templates into place - so I can start to refine the shapes to ensure that i get tabs in the right places to hold the front of the tunnel and also mark where it needs a trim.  Untitled Untitled on Flickr  Untitled Untitled on Flickr Not masses of progress, but still moving forwards - I now need to order more aluminium sheet, as the offcuts from the floor aren't quite big enough to make the panels as I have them templated - I might even try to make the passenger side and upper panel into a single piece, will see if that will work! |

|

|

|

Post by teamawesome on Sept 7, 2017 14:23:02 GMT

Looking good! I've not quite got to the part where I can start my Westfield, mostly due to the lack of a sump. Keep it up!

|

|

|

|

Post by browno on Oct 17, 2017 9:31:58 GMT

Cheers teamawesome - I was pleased to get mine started - but have now taken a step back before I can get the loom properly refitted! I have managed more progress again - having made up all of the panels, I then neatened them all up, and then it was time to get them all ready for fitting. Having pondered how to finish the bulkhead, I decided that I wanted them in body colour to tie in with the frame - so after some searching, I was able to find some vinyl in the correct (RAL6018) colour to match, and wrapped the panels - which match nicely.  Untitled Untitled on Flickr  Untitled Untitled on Flickr Then it was time to get everything lined up and drilled for riveting (and all of the holes cleaned and deburred.  Untitled Untitled on Flickr  Untitled Untitled on Flickr  Untitled Untitled on Flickr Then it was finally time to apply a generous bead of tiger seal to ensure good bonding and prevent vibration/drumming of the panels and start riveting into position.  Untitled Untitled on Flickr  Untitled Untitled on Flickr  Untitled Untitled on Flickr Overall, I am happy that it is looking pretty tidy as a finished job, especially with the tunnel in place (next job is to sort the tabs that located to the front of the tunnel and get that fitted).  Untitled Untitled on Flickr And since I am making progress - I decided that I was overdue some time to play in my other toy, so headed up to Blyton with Mazda on Track for an unseasonably sunny trackday at the weekend - which was very enjoyable!  Untitled Untitled on Flickr  Untitled Untitled on Flickr |

|

|

|

Post by browno on Nov 14, 2017 14:53:02 GMT

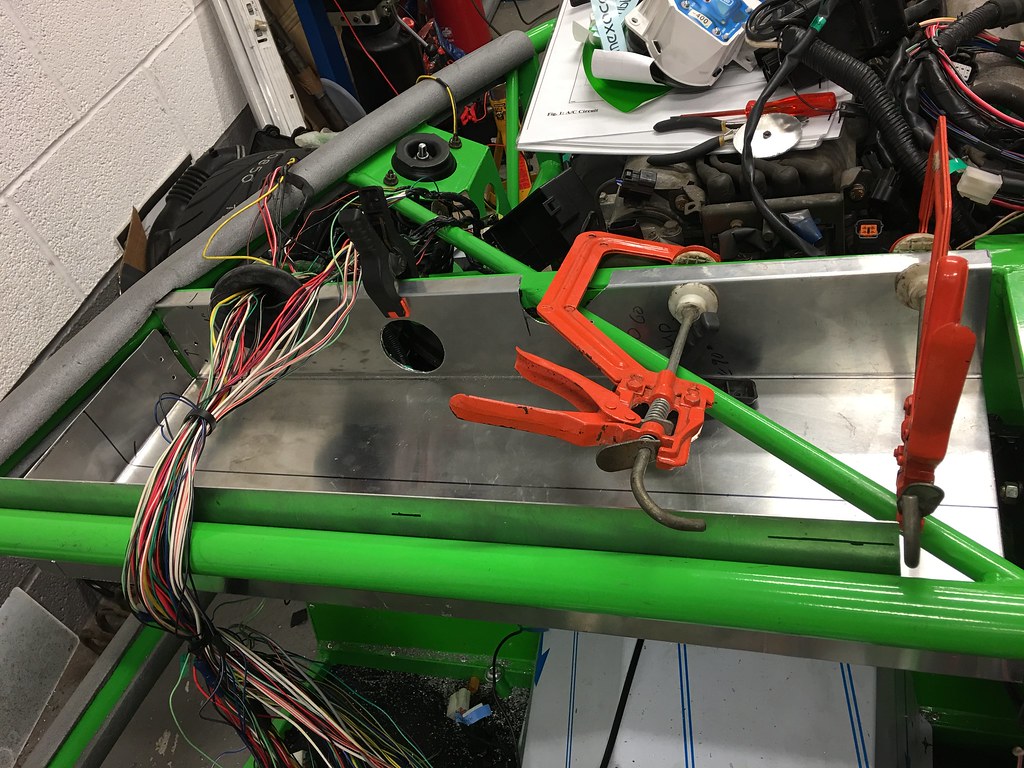

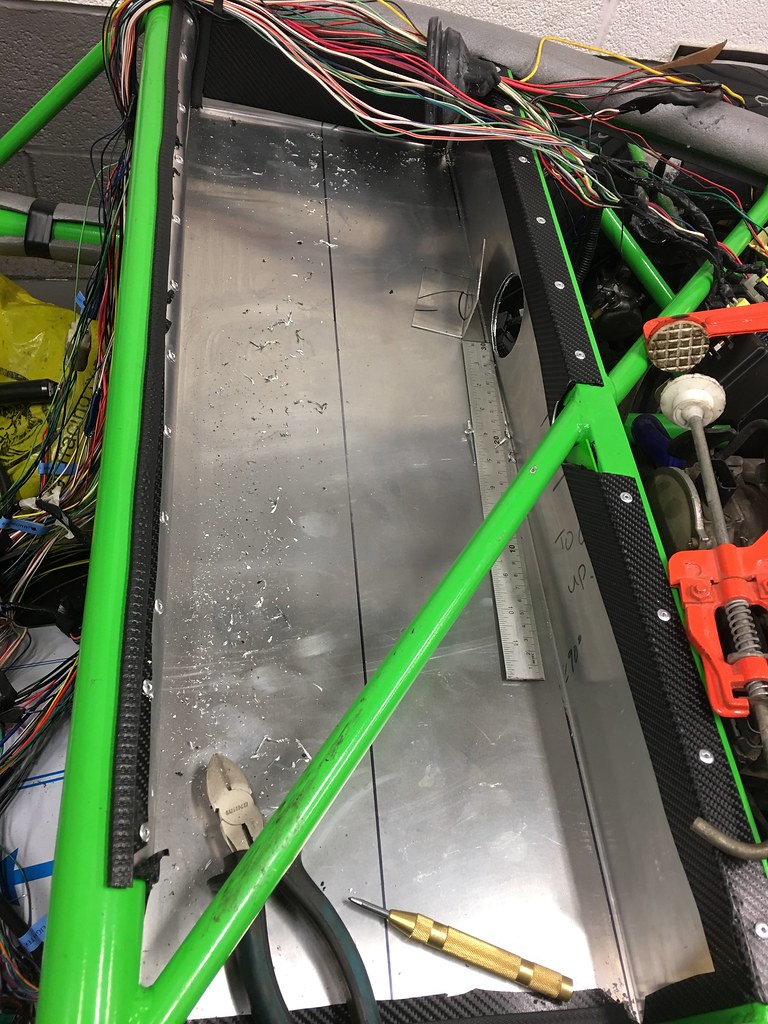

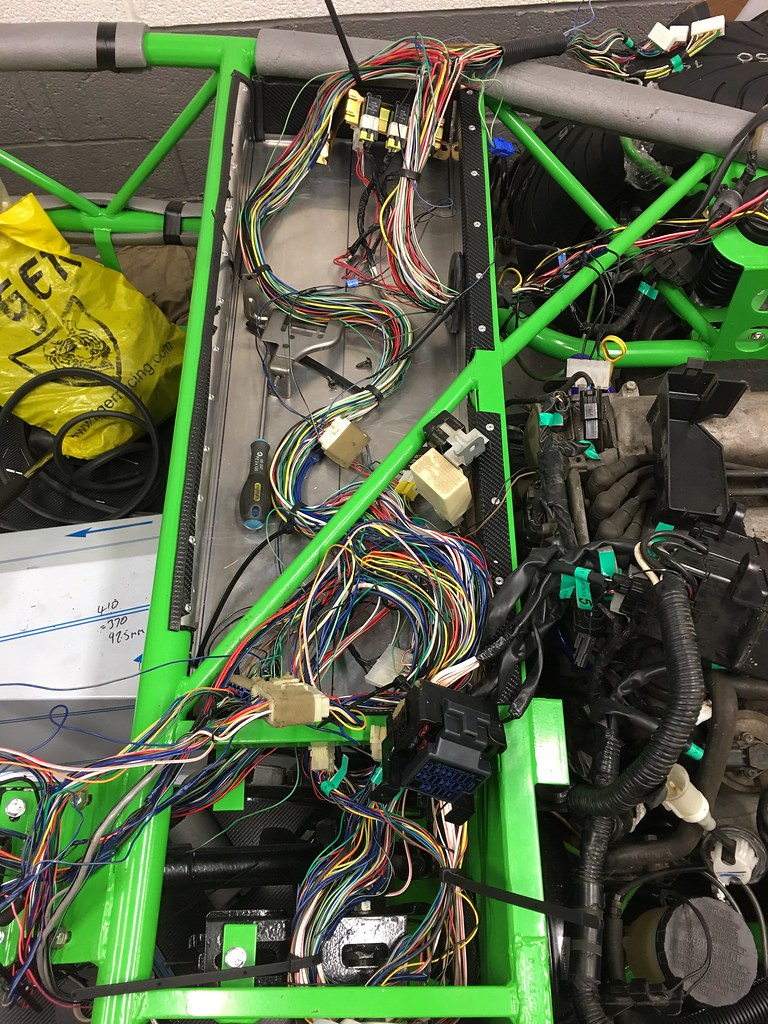

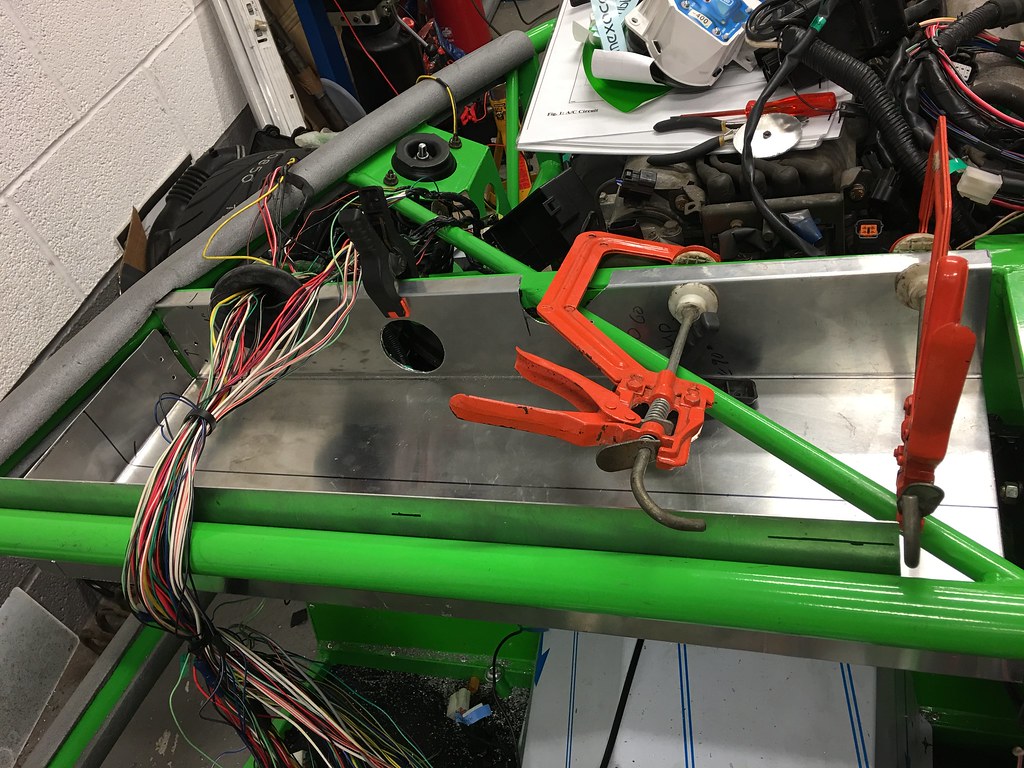

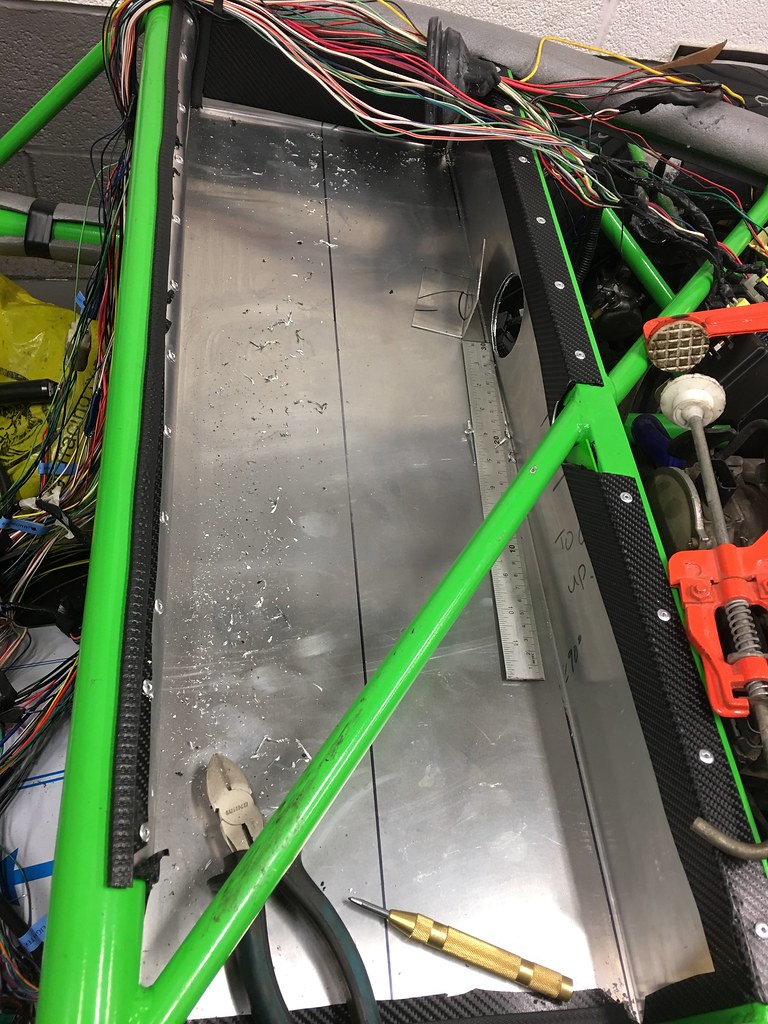

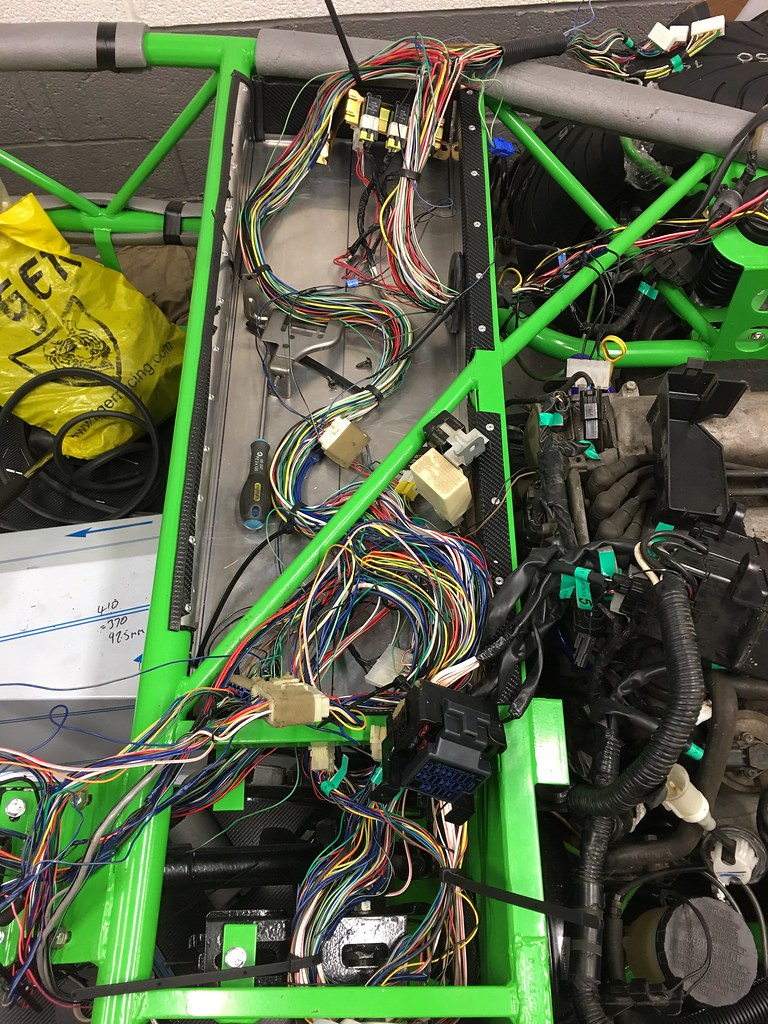

Long time, no update! I haven't forgotten about my build - but have in fact been busy doing various things in the garage - only some of them on the Exocet. After the previous update, I had started templating a wiring tray to hold the ECU and electrics neatly - so I cut out a sheet of ally and got it folded in the workshop at work - which left me with a neat tray that just need a little adjustment to fit into place:  Untitled Untitled on Flickr  Untitled Untitled on Flickr  Untitled Untitled on Flickr Then I took a break away from the Exocet as I wanted to finally get my mini sorted and running right - this has been a very long (23 year!) build, that I finally got MOT'd in March, but needed to get setup - so took it off to Peter Burgess to get sorted on his rolling road. It was a very steady drive over with a badly set engine meaning I couldn't drive over about 35mph without serious spluttering! Having worked his magic (and had a good chat), Peter has transformed the drive - and it now has a whole 51BHP (ish!) and drives much better, pulling happily now. This meant that I could take it out for its first proper drive - and then put it to bed for winter!  Untitled Untitled on Flickr video on the rollers: and since that, I have been starting to work on the Exocet electrics - firstly plugging the loom back into the key areas to get the engine to fire again, and then starting to strip out the unneeded wiring... so I currently have a car covered in large amounts of multi-coloured spaghetti - and lots of removed wiring!  Untitled Untitled on Flickr  Untitled Untitled on Flickr  Untitled Untitled on Flickr So I have now removed all of the wiring that I can see is unneeded (and that I dare remove!) and the engine still fires - so that's good! Next is to re-wrap the loom and then begin getting everything refitted and neatened up. However (as ever, there is always a challenge!), my brother has caught the trackday bug and has bought himself a clio 172 cup which we need to fettle a bit - and so that has been taking up some garage time too! |

|

|

|

Post by browno on Dec 5, 2017 13:02:59 GMT

Time for another delayed update - as the clio mentioned previously has needed rather more attention than planned - a lumpy, missing idle wasn't solved by swapping over engine sensors, and so deeper investigation was needed. It turned out that the cambelt that had been done by the previous owner had been fitted slightly out of time (the 172 uses a floating cam setup and timing (and belt replacement in general) is a pain - so we had to open it up, get it all retimed and put in a new cambelt, water pump and aux-drivebelt, which have resulted in it running much better!  Untitled Untitled on Flickr So with that sorted and back out of the garage (for now - we have a full set of new springs and dampers to fit to it next!), I could get back onto the exocet. First challenge was to check where the loom could run best and then cut holes in the bulkhead for the big wiring grommets (which required a decent holesaw!)  Untitled Untitled on Flickr and then with the nearside also done, position the wiring tray and drill that too...  Untitled Untitled on Flickr and with that done, it was then time to wrap and secure the wiring tray in place.  Untitled Untitled on Flickr Which I think now looks quite tidy from inside (although I know I will need to sort a way to radius the lower edge rather more for IVA - I am thinking some kind of tubing stuck on might do the trick) - so the next job is to get in with routing and tidying the loom up - I have already planned and rearranged the wiring for things like the engine fusebox to move into the wiring tray, so there may be some more creative work required to make sure that it all looks neat and is routed with minimal wiring on show. (and I also need to get a knife and ruler to tidy up the edges of the wrap too!)  Untitled Untitled on Flickr |

|

|

|

Post by Horney on Dec 5, 2017 13:38:15 GMT

It’s coming along nicely!

|

|

|

|

Post by teamawesome on Dec 5, 2017 16:37:14 GMT

Looks good. I'm just on the wiring for my Westfield. I think I've spent a good 60-70 hours on it. Take my advice, don't try to be clever and take out all the wiring you don't need.

|

|

|

|

Post by browno on Jan 4, 2018 14:00:30 GMT

So I think it is new year, new update time for the Exocet, as I have been busy with lots of stuff (including lots on the clio mentioned previously - completing a full suspension refresh and exhaust replacement) - but have managed to find some time to make a little further progress. Afraid you're a little late on advising to leave the loom alone though, teamawesome - I have already chopped out a lot of wiring. You are right, it does take a lot of time and effort, but I feel that it is right just to get rid of all that redundant stuff that I won't need. So, having fitted the wiring tray, I then started to feed the (still unwrapped) loom back into place - which left me with lots of spaghetti!  Untitled on Flickr So in order to try and clean things up and look more organised in there, I started adding some conduit, which started to improve matters.  Untitled on Flickr As I had to move things around in the garage to accommodate the clio on my ramp, I had to shift the nosecone (which had been suspended above my lift) - so briefly put it into place to see how it looks with the car on its wheels.  Untitled on Flickr Then I started wrapping the loom (with the hope that I won't need to access the wiring, so fingers crossed the loom thinning has worked out ok!), starting in the engine bay...  Untitled on Flickr Then I have started fixing things down in the wiring tray - with the ecu riveted down and the large fusebox secured to the chassis with a couple of rivnuts, and also getting some of the earth points located and bolted in, and I have started to locate the conduit also - using self adhesive cable tie bases (which will be securely riveted in place for IVA - as it seems that is required).  Untitled on Flickr  Untitled on Flickr So with this at this stage, I thought I'd better check that things still work, and I am glad to report that it still turns over and fires - and now that I have the earths properly fixed actually runs without cutting out after a couple of seconds - I think that the immobiliser wasn't properly earthed as I was stripping the loom and was killing the engine as soon as it fired. The horn even works too! I have also been busy shopping for more bits and have ordered most of the lights that I need along with hazard and foglight switches - so can get some more of the wiring completed. I will also be heading to the Autosport show in a couple of weeks, so will be on the lookout for some seats that might tie in with the car well without breaking the bank (currently thinking a pair of Corbeaus might be right), along with any other bits that take my fancy! |

|

|

|

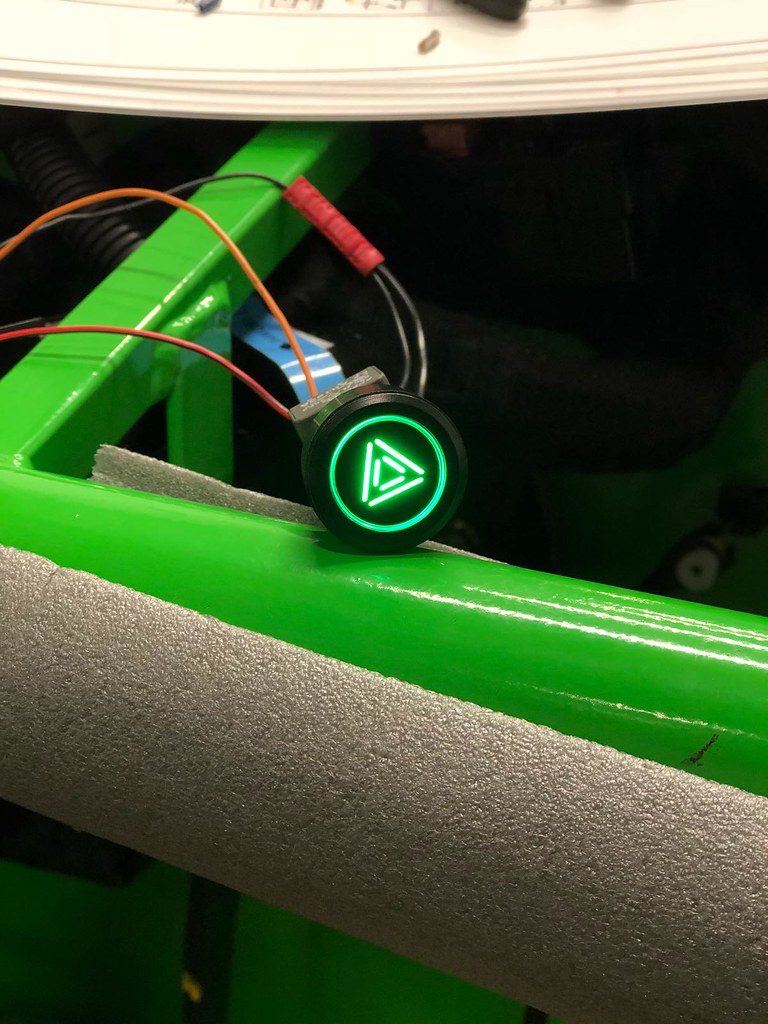

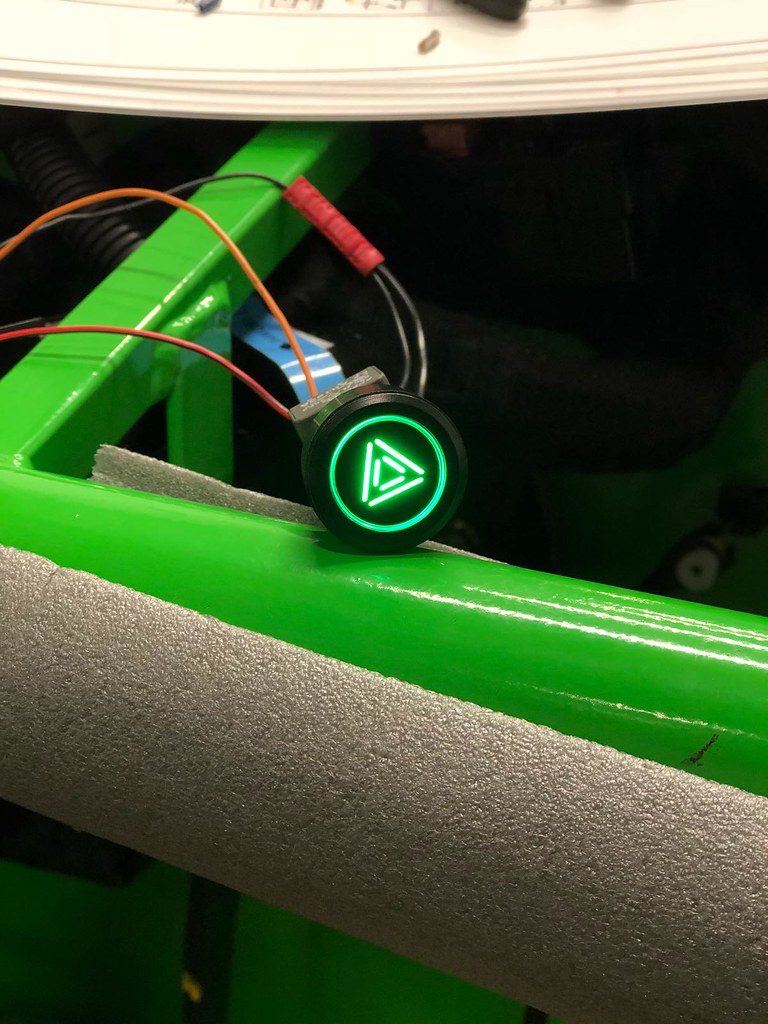

Post by browno on Jan 28, 2018 23:13:17 GMT

Time for an update again - and some more progress (but it is certainly getting to the stage where I there are a lot of jobs to do that have less to show for a lot of time!) First of all, I got some deliveries - including lights, so I roughly connected the wiring to test that all worked - and was pleased to see light!  Untitled Untitled on Flickr I also tried the wiring for my savage switches for the rear fog and hazard lights - which work and light up in a nicely coordinated colour...  Untitled Untitled on Flickr the only significant wiring issues have been sorting the earths on the panel lights and also discovering I had a dead instrument panel - which appears to be down to a broken track on the circuit board - which I will sort - but just want to check that the track hasn't broken due to high current leaking through the panel before I do so...  Untitled Untitled on Flickr I then started trying to tidy up some of the awkward bits that I hadn't got to and get some extra p-clips in some of the spots the IVA-man will be looking for - having bought myself a new drill and flexible drive to reach those tricky spots!  Untitled Untitled on Flickr Handbrake cable and fuel lines  Untitled Untitled on Flickr Rear braided lines  Untitled Untitled on Flickr Front braided line across the bulkhead behind the engine I then had a short break while I did a bit of work on my NC - service, replacement Lambda sensor and new front pads.  Untitled Untitled on Flickr Then it was time to finally get the cooling system hooked up with a new bend in the bottom hose (which will be secured for IVA) and get some coolant into my (temporarily held) Hyundai Getz header tank....  Untitled Untitled on Flickr  Untitled Untitled on Flickr Next, I bolted down my fuel tank (I went for M10 bolts at each corner with Nylocs underneath - I expect this counts as secure enough for IVA) - and then tested that the rear bodywork fitted correctly.  Untitled Untitled on Flickr  Untitled Untitled on Flickr I had deliberated about seats a lot and had swung between bare GRP and something more upholstered (like some corbeau/sparco buckets) but eventually settled on the lightweight approach and picked up a pair of MEV GRP seats, which I think will suit the minimalist nature of the car (and be a bit more weatherproof!)  Untitled Untitled on Flickr Then the latest fun and games - I started fitting the o/s rear wing stay and as I was tapping the hole in the hub, the M8 tap snapped off flush in the hole (just about visible by the driveshaft below)  Untitled Untitled on Flickr So, I had to whip off the hub and get it onto the bench - where thankfully, I was able to access the flutes in the tap and move it - and with some gentle persuasion thankfully managed to get the broken piece removed.  Untitled Untitled on Flickr  Untitled Untitled on Flickr With the messing around, it meant the hole was a little mangled, so I then drilled and retapped it to M10 to ensure that I have a secure fit, and got everything rebuilt. So that's as far as I have got for now, and the next plans are to get the wings mounted and get the lights all fitted and working as the next step towards being ready to go! |

|

|

|

Post by browno on Feb 14, 2018 23:35:35 GMT

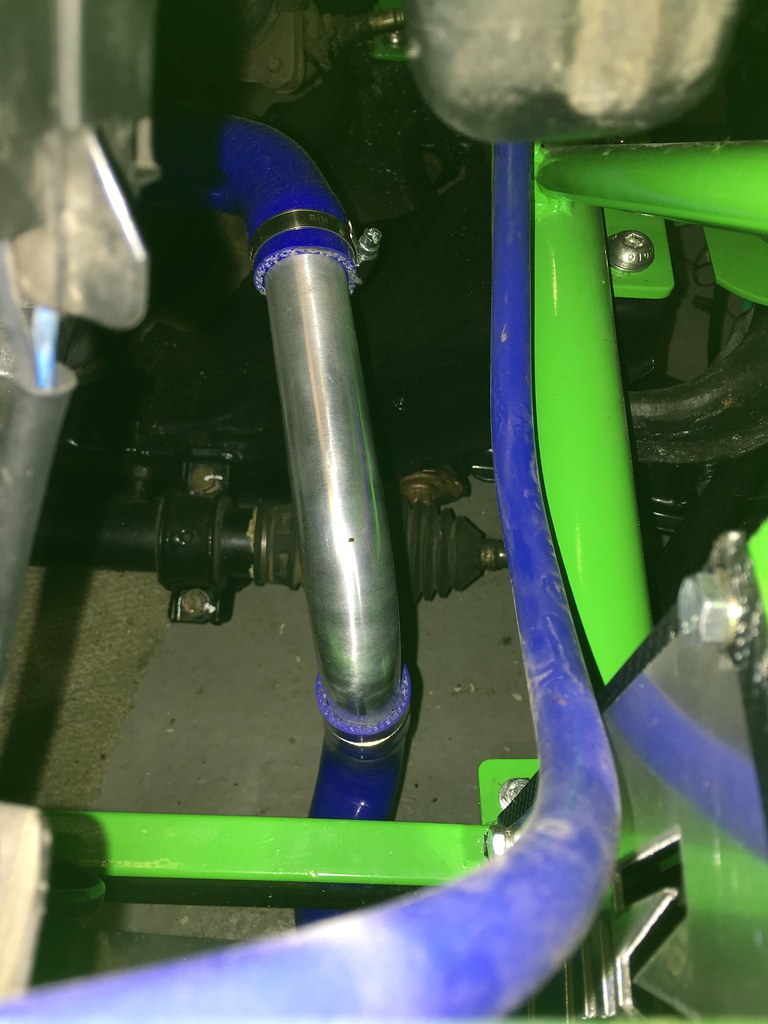

So, last time I was sorting out my rear wing mount, which I (eventually) got into place and so it was time to try and fit the wings...  Untitled Untitled on Flickr So the first job was to mount the rear light into the wing (with some edge trim to fill in any gaps), which I thought looked like a good start.  Untitled Untitled on Flickr then we could mark and drill the holes for mounting and get some tiger seal applied to fix it in place...  Untitled Untitled on Flickr The only slight downside is that having put the wheel on, I had put the wing about 5-10mm too far into the stay and the tyre is catching slightly on the outside of the wing - so i need to redo the mounting again - and of course the remaining three. In the meantime, I decided to move onto other things, so I have also bought LOTS of edge trim - figuring I will need plenty for IVA, I have ordered a 50m reel (which took some finding - but I discovered Rejel do 25 and 50m reels) - which has cost me about the same as buying 20m by the metre, and means I can trim everything and more ready for the IVA man. One thing that I had been wondering about was mounting the headlights - and I wanted to work out a mount that looked neat and tidy - so having sketched a few things up, I got some Aluminium bar machined up with a radiused end and suitable holes for mounting the lights and to bolt through to the frame - I did have to do a rethink on the dominator light threads having originally made (what I thought was) M8 thread, and realising the lights didn't fit - I then measured and rethreaded to the correct 3/8" UNF thread for my lights. This then allowed me to test-fit, which I thought looked a good start before then painting the mounts up and fitting the lamps:  Untitled Untitled on Flickr  Untitled Untitled on Flickr Then I added my indicators onto the sides of the lights and started wiring as neatly as possible, and I am very happy with the result - and something that I think is a nice touch at tidying up the front end.  Untitled Untitled on Flickr  Untitled Untitled on Flickr  Untitled Untitled on Flickr So I am happy with my progress so far - and have done a few other bits including mounting my header tank properly (if there is one thing I will change at some point, it will be to get rid of the blue hoses, and get something more in keeping with the green and black of everything else...)  Untitled Untitled on Flickr |

|

|

|

Post by myothercarsa2cv on Feb 15, 2018 0:35:10 GMT

Really neat work on the headlight mount 👍🏻 no option for a smaller rad at the front there? The MX5 one is so wide...

|

|

|

|

Post by teamawesome on Feb 15, 2018 14:37:50 GMT

How far away from IVA are you?

|

|

|

|

Post by browno on Mar 4, 2018 22:42:28 GMT

Cheers for the comments again - on the radiator, I haven't investigated anything smaller - the bodywork is designed to fit over a standard NA rad - but I might look to something a little narrower if I eventually go turbo later on. On the IVA, I am not too far away, in fact I called up the DVSA last week and asked them how far ahead they are booking - I think once I get the bodywork all mounted, then I will likely submit the paperwork to get an appointment booked to give me a deadline to finish off the final round of sorting and fettling - if anything so that I don't over-think the final prep! Afraid that I have been busy tinkering for the last few weeks - so am overdue another update to the thread! I have been making more progress - although I am now getting into some of the fiddly bits that are really taking quite a bit of time and thought to get right (and even then, some things are taking a couple of attempts until I am really happy that they are up to standard. First job for this instalment was to clean out the garage (and get my brother's clio out!) then I could move the exocet forward on to my lift for the first time (and in fact the furthest it has so far moved since being on it's wheels).  Untitled Untitled on Flickr  Untitled Untitled on Flickr And to go with the wings being sat in place, we also offered up the next addition - which is a pair of new g-type side panels from MEV, which I saw and thought would finish off the sides rather more neatly than the standard black plastic panelling.  Untitled Untitled on Flickr The next job was then to actually drill the remaining three wings and offer them up into place:  Untitled Untitled on Flickr and then tiger seal them into place with some suitable load on each wing...  Untitled Untitled on Flickr Next, we carefully measured, marked, measured again and then cut out and mounted the fuel filler and fog/reverse lights in the rear tank cover.  Untitled Untitled on Flickr Which meant we could then test-fit the cover onto the rear end to see how it is all going to look (I have ordered a number plate light, but think it may be too small to light the whole plate - time for some more IVA manual checking and shopping, I think).  Untitled Untitled on Flickr Before the cover can be properly fitted, the pipework and wiring all needed tidying up  Untitled Untitled on Flickr and then getting the fuel filter mounted - using the tank mount which also doubled up as a good earth point.  Untitled Untitled on Flickr In the meantime, I have been wondering what to do about an exhaust, and after a bit of an eBay session came up with something that will at least provide me with a solution that's neater than the big standard box hanging out the back, but that isn't too expensive to replace when I eventually go turbo and might want to replace the whole system (as I currently have the less-used 475mm cat).  Untitled Untitled on Flickr and with a bend and some clamps (and some highly secure cable ties) I could test fit it, and I think it looks pretty tidy.  Untitled Untitled on Flickr So there is some more work to do, next major job being to get the rear cover fitted and sorted, which I hope to get onto this week. |

|

Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr Untitled by brownotribbs, on Flickr

Untitled by brownotribbs, on Flickr

le sigh

le sigh