|

|

Post by Horney on Oct 17, 2017 22:01:55 GMT

Nice progress bud!

|

|

|

|

Post by NurseHolliday on Oct 18, 2017 9:27:18 GMT

Yeah, looks great!

Did you have fibreglassing skills beforehand, or have you learnt just for this build?

|

|

|

|

Post by teamawesome on Oct 18, 2017 11:37:16 GMT

This is my first time. Luckily it's out of sight so it just needs to be strong rather than pretty.

|

|

|

|

Post by teamawesome on Oct 26, 2017 19:52:26 GMT

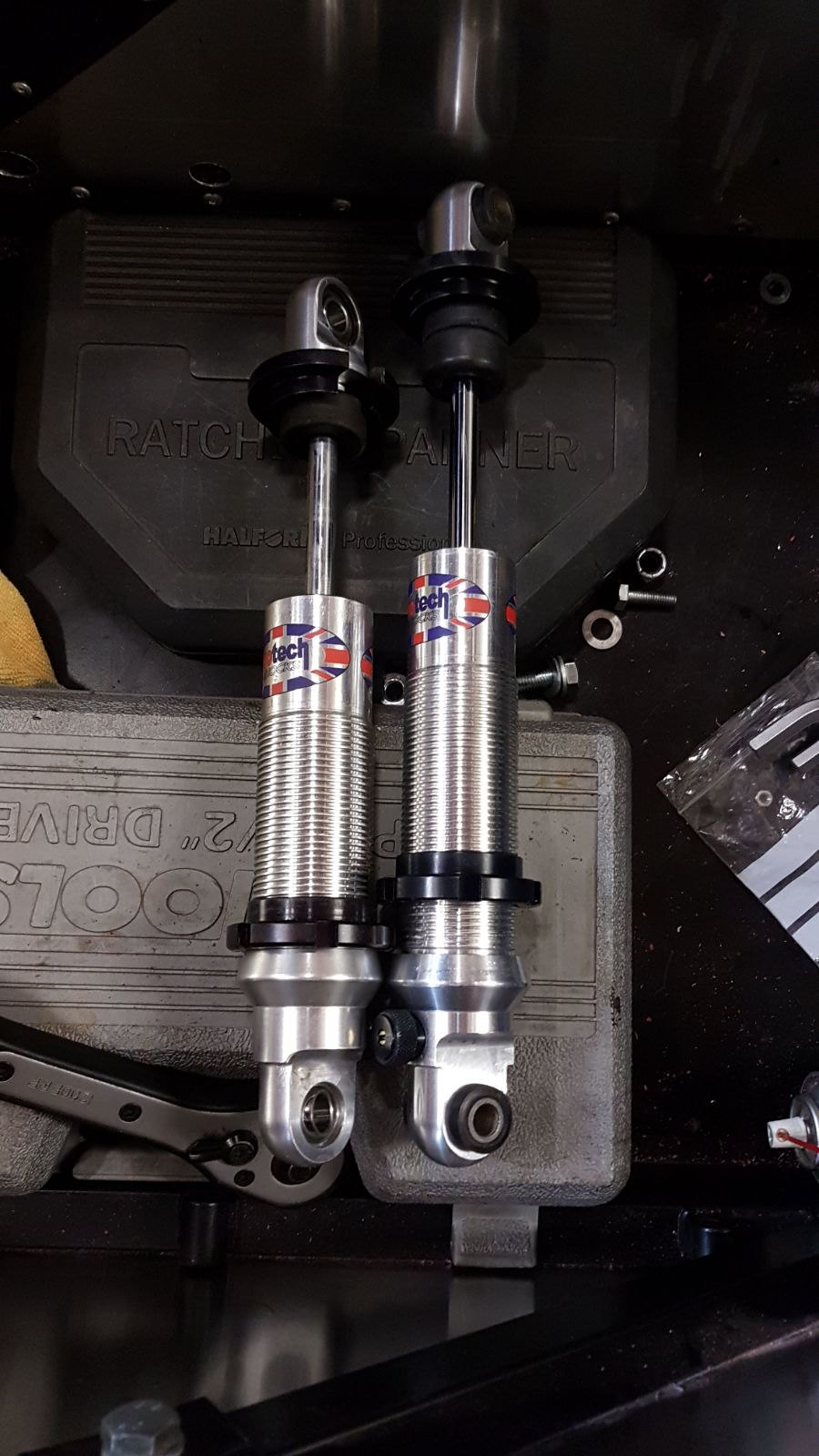

A few more things have been doen to the car over the last few days. One of the things we couldn't do last time was the lights. We were undecided about the placement of the rear and the front indicators should've had a spacer block for IVA rules, but they weren't in the kit. In the end it turns out that the IVA rules no longer require these but the manual still references them. hey are a little complicated to do as the measurements are quite precise, but we could do the rear. Really we had a lot of choice of where they could go. We could go with the Westifeld suggestion of level with the other rear lights but they aren't eaxctly the most even of things it turns out, They LOOK level but that doesn't mean they ARE! We could go with the Caterham method, right down at the bottom of the tub, but that is possibly too low as the IVA rules sate they must be at least 25cm off the ground and my car isn't on it's wheels yet (come on G19, 6 months for a sump is taking the piss!). In the end we went for a comprimise and put them in the middle. To be fair the lights are a bit blocky but they are sort of iconic to these cars. I think they look about as good as they ever can (although you can get them in carbon for a 15g saving each).  As I said in the last post we had ordered new suspension for the front as the standard items are only 12 inches and that leaves the wishbones level at full extension, roughly where I'd want it when resting. Obviously this wouldn't be the case! The new shocks are just 14 inch versions of the ones I already had, except they have bonded bushes rather than rose joints. I believe this will actually be better for a car that won't just be a track car.  The springs are bought separately and I needed 9 inch instead of the 7 I had. The choice is almost too much but I settled on the 325lb springs. From my research they seem to be a good choice as a road/track car as mine will be.  For those interested I believe Protech do make suspension for the MX5 but I've not known anyone to use them. They make very good kit, certainly for the kit cars anyway. The results are in for the actual benefit this change makes. I think it's pretty dramatic.The right hand side in the below pic shows the standard size and the left hand side shows the new suspension. I think this will be much better for the handling as I can get it riding where it needs to be without risking running out of travel.  As always, feel free to let me know what you think! |

|

|

|

Post by baconsarnie on Oct 30, 2017 12:15:23 GMT

Believe Protech made the first generation of P5 shocks. Very good by all accounts but did have problems with corrosion resistance. Don't know how closely related the latest offering are to the P5 shocks but I imagine they made struggle to find many buyers when up against the "interest free credit" taiwanese offerings! Love the progress on this btw  |

|

|

|

Post by teamawesome on Oct 30, 2017 17:45:26 GMT

Hopefully I won't have to deal with any corrosion, I will try to keep it dry. I've seen a lot of cars that have their original set after 5 years on the road so I'm ok with that.

|

|

|

|

Post by baconsarnie on Oct 31, 2017 15:18:26 GMT

Yeah tbh we are talking maybe 10 years ago? Expect they'll have their coatings sorted by now! Wouldn't expect any problems on a well maintained track car  |

|

|

|

Post by teamawesome on Oct 31, 2017 20:56:03 GMT

From what I hear they can still have a few issues but from the sound of it it's mainly cosmetic.

|

|

|

|

Post by teamawesome on Nov 16, 2017 14:03:24 GMT

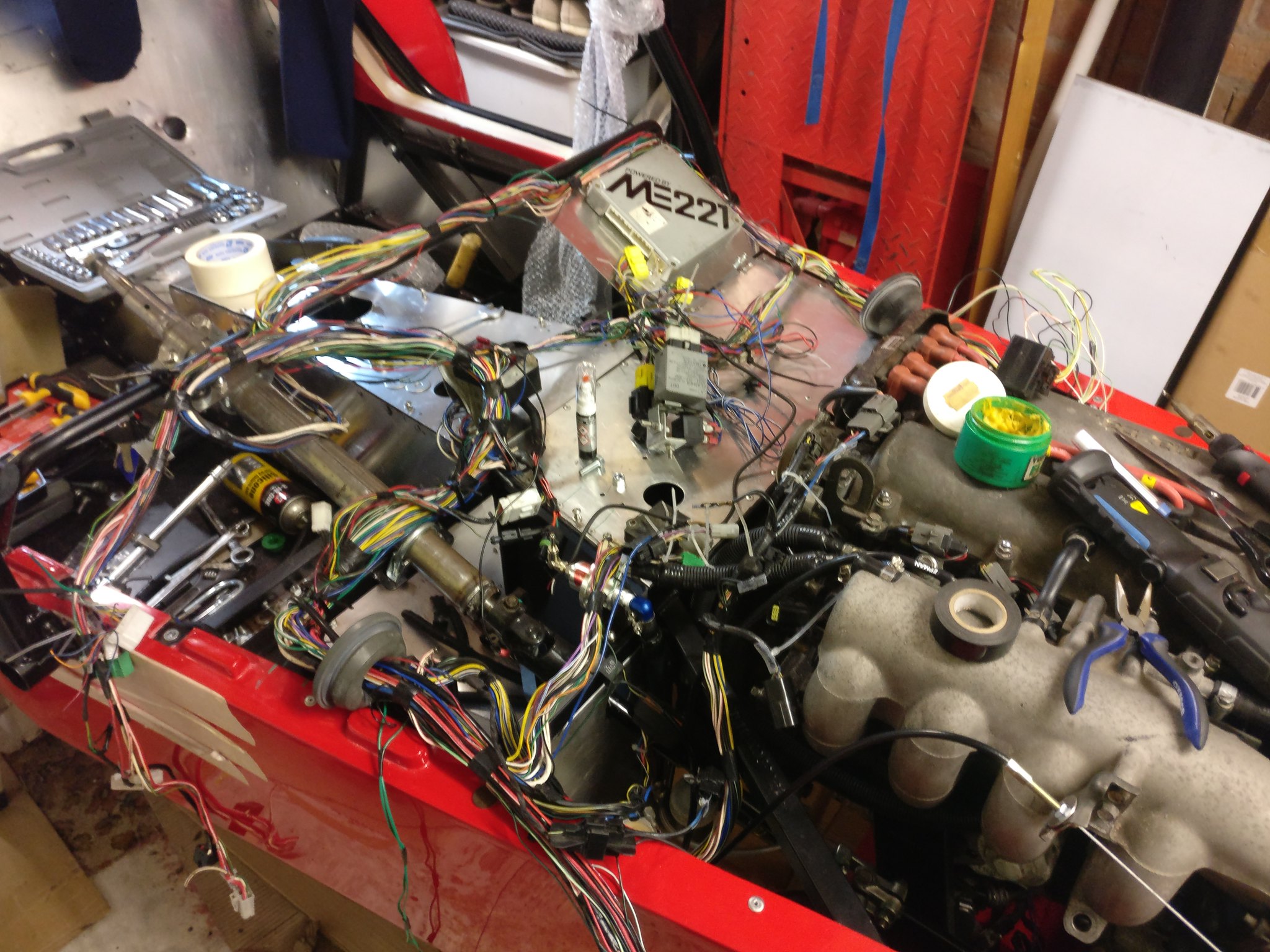

The work seems to be slowing down considerably now. This is mainly down to the fact that it's wiring, wiring and little bit more wiring at the moment. I hate wiring...... We've been trying to do it as systematically as possible, focusing on individual plugs and sensors one at a time. So far we've had to shorten the wiring to the headlights, make changes to the indicator and sidelight wiring, add wiring to the fan switch in the radiator, add wiring for a new horn as I lost the old one, shorten the wiring for the diagnostic box, lengthen the wiring for the brake switch as that is now a pressure sensor in the lines rather than a switch on the pedal and last we've added wiring for the brake master level switch as my MX5 didn't have that (although happily most of the wiring was there. Thinking about what we have left to do is just as big a list with adding dash sensors to the loom, knock sensor wiring, all the dash needs to be done............ This just goes on. There rear end wiring is complete now. All plugs are added and hopefully they'll all work when I add a battery to the car. So far all wring is untested so I can only hope we haven't completely messed things up. It's messy work too, here's how it currently looks.  Far from the prettiest sight but not as bad as it was at the start of the weekend. Slowly but surely I feel like we're making progress. The next plan was to fit the indicators so we could see exactly where we had to extend the wiring to. This went well but they were ever so slightly off. When we took them off we decided to tidy the length of the studs holding them on. I wish I hadn't bothered. I ended up crossthreading the nut but it really didn't feel like it so kept going unaware. In the end the fixing broke looks so we've had to get the epoxy out. Not a shining example of how to assembly one of these things but at least it's not visible. I hope it solves it as they're £50 each to replace Now on to a topic that has been mentioned a lot in this thread with very little happening - the chopped and winged sump. I contacted G19 Engineering in April and placed an order for this, and Doug was keen to build it. Over the last 6 months he has not managed to finish it, and I'm really rather disappointed in his communication, or complete lack of it. Around 8 weeks ago he said it was 2 weeks away from completion. Nope. He hasn't responded to a Facebook message since May. He doesn't answer the phone, and when his colleague takes a message he never returns my call. He says it's not an order as no money has changed hands, but then he did take my credit card details in July but didn't charge anything. Essentially my experience with Doug has been piss poor. His manifolds look great, but custom work seems beyond his production capabilities at the moment. With the sump looking like it'll never be complete I have sourced a new supplier! YAY! I had a sump cleaned up (see below, never seen one so clean) and have delivered it to them. They've completed their design should be complete before Christmas, so roughly a 6 week lead time which is reasonable. I can't wait to have it in my hands so I can finally get it fitted and get the car on the ground and be able to see if it fires up. Beautiful sump with a cat helping out....  Fingers crossed it'll be fired up over the Christmas break and from there it should be easy-ish to get it ready for the IVA. |

|

|

|

Post by teamawesome on Nov 22, 2017 20:15:02 GMT

Finally things are moving on with the sump! After G19 Engineering failed miserably to produce anything other than delays and excuses I got in touch with Lavron Composites based in Reading to get it done. Jordan, the owner, was very enthusiastic to do this and had a lot of ideas before I'd even placed my order. He's done a lot of fabrication for rally cars and, as the name suggests, a lot of carbon fibre work. He's made a start on it and here's how it looks so far Bottom cut off  Checking the level of the oil pick up. Looks like it will need to be shortened slightly.  Standard baffling is now missing so will require one making. It will have one with viton flaps to stop oil getting away on track  Last but not least we have a mock up of the wings to keep the volume of oil the same or higher than standard.  I can't wait for this to actually be finished. I have more wiring to do this weekend but I can't test too much of it until this sump is done so I can turn it over. |

|

|

|

Post by dadbif on Nov 24, 2017 15:58:16 GMT

When I built my wide body Westfield in 1996, I fitted a C20XE Engine,, like you I need more ground clearance for the sump, an Opel manta had an winged alloy sump and used the same block, so we chopped the bottom off the sump and extended the wings... then welded a nice thick flat ally plate on the bottom.

|

|

|

|

Post by Horney on Nov 24, 2017 18:12:30 GMT

Glad you’ve sorted your sump issue.

|

|

|

|

Post by FFS Corders on Nov 26, 2017 10:15:07 GMT

Good to see someone engaging in the work you are wanting

|

|

|

|

Post by melx5 on Nov 26, 2017 10:57:25 GMT

I'm probably talking crap (nothing new there) but could you use external oil tank/s to increase the volume of the sump?

Think swirl pot

|

|

|

|

Post by teamawesome on Nov 27, 2017 18:13:23 GMT

Possibly but it starts to get expensive and that takes up space in the engine bay. Much easier to just modify the standard sump.

|

|