|

|

Post by teamawesome on Feb 15, 2018 8:04:09 GMT

It seems like I'm doing something I've never seen here, I'm actually replacing a short nose crank pulley. I had an issue a couple of years ago where the crank pulley was wobbling. I took it all apart and the crank was actually in really good condition, only an extremely tiny amount of wear. I did the loctite fix and rebuilt it all but it still wobbled. I left it at that because the car came off the road quickly afterwards for this build. Fast forward to a few weeks ago and I had to take it off to delete the front thermostat housing. When rebuilt then it was still wobbly so we decided to look a little deeper into why. Turn out the pulley has quite a lot of runout! Not sure how, maybe an over tightened belt of something. I've taken the plunge and £100 has bought me this  Hopefully we'll get the pulley running true with this. |

|

|

|

Post by FFS Corders on Feb 15, 2018 8:10:38 GMT

Cheaper and easier than fitting an LNC. Hope it stays true for a while as well

|

|

|

|

Post by teamawesome on Feb 15, 2018 9:20:54 GMT

I think if it ever gets a full rebuild I'll get a LNC and oil pump and just go for it, but I'm hoping it won't need to. 250bhp should be fine in a 600kg car.

|

|

|

|

Post by teamawesome on Mar 12, 2018 19:11:09 GMT

Some exciting parts have arrived! I was looking at turbo manifolds for the 1.6 and it quickly became quite clear that the availablity for these engines was limited, even more so when it has to fit on the Westfield. Over the course of a few months of back and forth with a few companies there were none that would clearly fit. There was the option to wait for the G19 manifold but they seem to be pushed back every month and I'd hate to support that company if he'd even sell me one after my review of them! In the end i stumbled across DaveFab and they actually make a Westfield specific manifold for the 1.6 and 1.8. I took delivery last week and here it is:  Looks pretty good and should be strong enough for what I'll throw at it. I've ordered some gaskets and I'll try to get some studs. I'm struggling to find M10x1.25 inconel studs but I can find titanium, so hopefully they'll be almost as good. The aim is to have this fitted on my next trip up to the car, I've made a start on the oil lines so we should be good to start the car! |

|

paul20v

New Here

Usually under a bonnet somewhere

Usually under a bonnet somewhere

Posts: 26

|

Post by paul20v on Mar 23, 2018 12:42:17 GMT

I haven't long sold my westfield "mx5 donor" was a fun car even standard 1800 power so turbo,d will be mental  |

|

|

|

Post by teamawesome on Mar 26, 2018 21:53:40 GMT

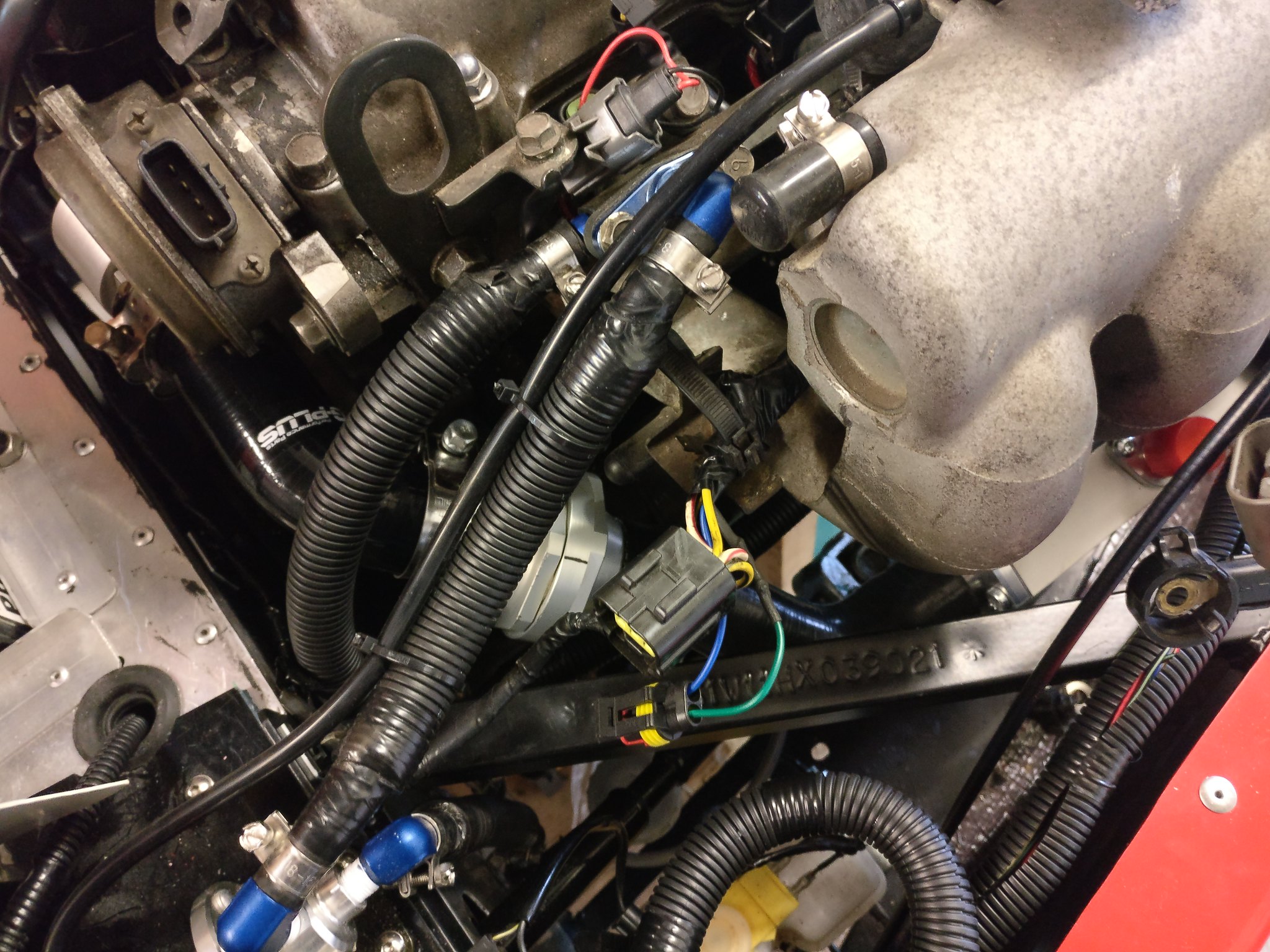

It's been a while since I've been to work on the car but I had a chance this weekend. Started off nice and easy with the change of the front pulley. I'd had problems with it for years and I assumed it was the short nose crack but it turns out it was just the pulley. I reckon it's had a belt overtightened at some point and it was misshapen. Bet you'll never seen a brand new one of these going on a car any time soon.  Moved onto the turbo kit next. I'd made an oil line and fitted that and then moved onto the manifold. It went on with little bother, a little filing required but nothing major. I then split the turbo as I know it would need to be clocked. Got it loosely fitted and this was a beautiful sight at last.  As with all things with the Westfield though it wasn't all straight forward. Unfortunately the downpipe will need a little modifying to fit as it currently hits the engine mount. DaveFab have been great though and I'm sure it'll come good. After this I got to get the welder out. The actuator is designed to fit on the head but the turbo in this design is about an inch further away from this location than the last owner. Easy fix, I cut the actuator arm and extended it using some tubing we had laying around. My welding may need a bit of practice though....  Next on the list was the upgrade to full sequential injection. Seeing as I've modified the loom so much I may as well add 2 wires to the loom to get this upgrade. It's supposed to give a better idle and mine used to suck, so let's see. Firstly I made a huge error, I wired it up as though cylinder 1 was at the back on the engine. I'm not sure why, maybe I was tired or just not concentrating but it was a silly mistake that I had to go back and fix. If you're interested in going down this route I'd suggest you look into getting extra pins for the plug before you start! I knew I'd need them but had some spare, bit the were the wrong size and I had to really search through my bag of offcuts for something else. Luckily for me, some plugs on the rear harness use the same pins and I had cut them out already, so I'm now all modern with my sequential injection! |

|

|

|

Post by ben99w on Mar 27, 2018 21:14:28 GMT

I've enjoyed this thread. I had a westfield with 180bhp ford zetec in. Sold it then went to my turbod 5, but I still miss it.

Anyway you mentioned struggling to get inconel studs. I had to get them from il motorsport in Germany. You can order them from their website and delivery is pretty quick. I'm not sure titanium has the same thermal property as inconel which is the reason for using it rather than strength.

Ben

|

|

|

|

Post by teamawesome on Mar 28, 2018 7:48:15 GMT

I tried to look into the thermal properties but didn't understand any of it! It all looked like steel, inconel and titanium were very similar, which I know is wrong. IL Motorsport didn't do the M10x1.25 I need so I just bought some others and will see what happens. They were from a reputable seller who claims to have had them made specifically for turbo applications. Time will tell.

|

|

|

|

Post by dadbif on Mar 28, 2018 16:12:01 GMT

I’m enjoying the thread too, not too dissimilar to mine that I built over 20 years ago  |

|

|

|

Post by teamawesome on Apr 3, 2018 10:25:55 GMT

Just a small update from this weekend. I spent a lot of time tidying the wiring ready for final fitment. The rest of the time was spent fitting this:  The turbo is on permanently now. I have made up some oil lines and coolant lines. Since I removed the front thermostat housing I have taken the coolant feed from the air valve on the inlet manifold and plumbed it into the chrome breather pipe to route it neatly to the turbo. Obviously I cleaned it out first! The return has been routed to the coolant reroute at the back of the head. Pretty much it for this weekend. Not a lot left to do, I think the IVA papers will be sent off in a few weeks! |

|

|

|

Post by teamawesome on Apr 18, 2018 10:10:03 GMT

We got quite a lot of work done over the weekend. Up to this point it's been a case that there's been many hours going into the car but it always seems to still be a mess and there's very little visual progress even though I know the work is progressing well. This weekend saw that trend start to turn around slightly as the wiring starts to find it's final home. I'd bought some heat reflective wire civers for the harness as it's very close to the turbo and considering it's low price it was actually very good quality. Maybe not as good as the DEi stuff, but this was £10 each rather than £50 each so I think I'm still on to a winner. You can just about see it in the first picture. As well as getting the wiring on the passenger side sorted out I plumbed in the boost controller. I decided to use the turbo signal line rather than taking it from the intake manifold, I figured I'll be using a boost controller anyway so I can fine tune it to my required boost. We also went on to secure the wiring for the gearbox and cover all the drivers side wiring but this will be secured later. As you can it's a littler better, but still needs further tidying.  We then focused our attention on the laminova oil cooler. We'd decided that the best location for this is just under the intake manifold. It'll hang from the hole that the brace used to occupy, as this hasn't been there for years, and we'll have to make another on the other side to keep it stable. I really though the coolant line was going to be a pain but it actually turned out OK but using hoses I already had lying around from the build. The Mazda hoses have had a knack of being just right for my ideas, luck rather than judgement if I'm honest.  Final job was a simple clean up of the interior and get the seats in roughly the right place, ready to be fitted next time. The passenger seat will be a fixed location and the drivers side will be on an adjustable runner. I think they will go on with the carpet on the next trip to the garage.  The main jobs left are: -Finish the coolant lines from the cooler to the radiator -Fit the seats and carpet -Fit the dash -Final fit of wiring and tidy for the front and rear lights -Cycle wings on and fit side repeaters -Exhaust fitted -IVA prep I'm sure I'll find more! |

|

|

|

Post by teamawesome on May 7, 2018 12:54:00 GMT

Got another new part for the car. In readiness for having my downpipe modified to fit I have bought the exhaust from Westfield a little early. It's not the cheapest of things but I couldn't find one elsewhere so I had to bite the bullet.  It's 2.5inch so should be perfect for what I need. I'll just have to have someone make the downpipe meet the can, I'm tempted to trailer it to DaveFab and have them do it at the same time as the downpipe changes as I'd also need to intercooler piping made up. |

|

|

|

Post by joeytalent on May 7, 2018 14:31:27 GMT

Got another new part for the car. In readiness for having my downpipe modified to fit I have bought the exhaust from Westfield a little early. It's not the cheapest of things but I couldn't find one elsewhere so I had to bite the bullet.  It's 2.5inch so should be perfect for what I need. I'll just have to have someone make the downpipe meet the can, I'm tempted to trailer it to DaveFab and have them do it at the same time as the downpipe changes as I'd also need to intercooler piping made up. Excuse me whilst I wipe away this drool. |

|

|

|

Post by teamawesome on May 22, 2018 12:26:48 GMT

It's really starting to feel as though we're near the end of this build now. I can see a few more weekends working on it and a trip for an exhaust to be built but I think we're nearly there. I spent the weekend just gone on a few of the finer details. Firstly I wasn't happy with my reverse and fog light, the Westfield ones are quite sharp and I felt as though they were a risk to the IVA. Westfield suggest running some edging around them but this was a pain so I bought new ones that were a little rounder and they are supposed to be IVA compliant. Next we moved onto the interior and cage final fit. I decided to go with carpet as it looks the best from what I've seen and it covers anything that could be classed as sharp. This is fitted using good old velcro and contact adhesive and it seems to do the job very well. What do you think?  We also had to take the cage off as the rose joint had seized on the back. Nothing too bad, but I couldn't adjust it in situ. Thankfully I should never have to remove it again now it's on and fitting well. The seats are now in, but not bolted down. The car is resting on stands directly below the mounting holes so I can't get to them.  They look pretty good in my opinion! Lastly we did the final fit of the dash. This uses the Mazda plug so it's a plug and play solution. If I ever need to remove it I can with just the 9 bolts holding it on and 2 plugs. Hopefully it all still works, it did a few months ago when we tested it. Again, this came out better than I expected it to and it's something I'm rather proud of.  Hopefully in 2 weeks time we'll be going for the first start. Now that will be exciting! |

|

|

|

Post by teamawesome on Jun 5, 2018 14:34:50 GMT

Only a very small update as it's tedious tidy up work at the moment, but it holds fuel and no leaks! I had an issue with a fuel pump not working but it turns out it only works when plugged in.

|

|