Post by cat on Jul 7, 2018 13:25:14 GMT

So I was over at mx5trousers or whatever it was called and I never had a build thread, because gosh that's indulgent. Also I'm doing nothing new whatsoever, so who cares if I post some pictures of something there's pictures of elsewhere because those are the pictures I looked at to work out what to do with my rust rocket.

I had just been dumping my list of failures into the 'What Have You Done To Your Mx5 Today?' thread, but since I've been uprooted and those babblings are forever lost into the way back when machine, I thought I'd start my own whinging here where it can be safely ignored.

So, what's the state of play?

A thousand years ago I bought a 'cheap' (lol) import eunos from down the coast in berwick and drove it around for a wee bit, took some bits off and tried to clean them a bit, tried to stop it leaking, bought a cover to stop the rain getting to the leaky bits and got on with saving up for some turbo bits.

I got:

An intercooler from a dealer who doesn't deal any more.

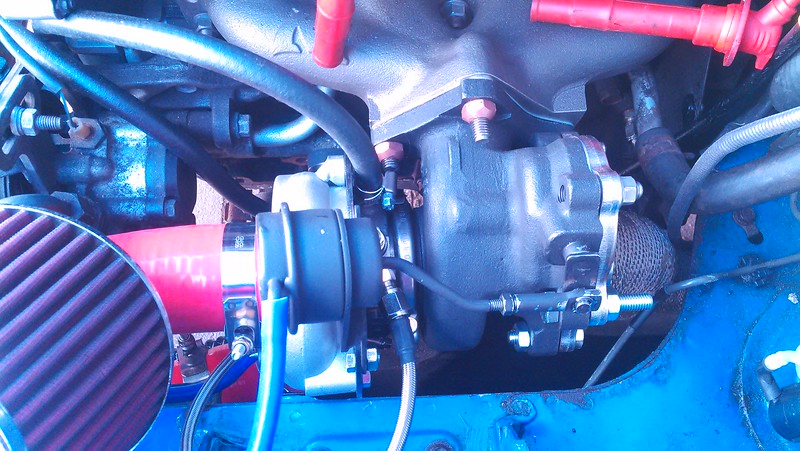

A manifold, downpipe and ME221 from a dark coloured feline shop along with a turbo fitting kit (some banjo bits and bobs and water lines and a nice bracket that came in useful.)

A TD04 from some engineers with a prime number, and i got their dipstick oil dribbling thing so as to avoid drilling the pan to dribble the oil since I couldn't for the life of me fathom the relationship between drill bits and fitting tapers. They also supplied a hot air measuring thingy and a better TPS

I don't recall from where I bought the AEM wideband which shows different numbers on the display than the ECU uses, buh.

As you might expect, none of it went together and some problems needed to be overcome:

Studs locked so tight into the block as to be terrifying, they eventually came out trailing bits of aluminium dust.

Nuts fusion welded to the studs that won't come off with ANY degree of violence I can deliver so new studs and nuts needed.

The manifold caused the turbo to sit too low for the dipstick return to be viable.

The downpipe to cat stud needed to be surgically cut out, knackering the studs in the cat which I drilled out and milled out into bolt holes.

Turbo 'cold' side pointing straight at the lower coolant hose.

Turbo in hole being in the way of the power steering reservoir hose.

Turbo needing to be clocked to the one place it would fit, and consequently needing to modify the waste gate bracket to remotely fit.

Aaaaanyway, after leaning on a local contact with a welder (despite learning to tig weld, I've never yet afforded a welder) and spending about a thousand quid more than I wanted to (I think that's getting off lightly, right?) my car goes both wooooooosh as the air goes in, and wubwubwubwubwub as the throttle closes because I don't yet have a waste gate, but ALSO goes down the road... to the MOT station, where it fails on a knackered brake caliper on which the handbrake doesn't, and a front spring which shouldn't be in two bits.

Now whilst this is a terrible trauma, it's ok because neither of those bits are bits I've messed with.

The replacement springs are sitting on the passenger seat, and the replacement reconditioned brake caliper has just been ordered, so when that turns up, I'll book it into a local shop to get them added and then hopefully it should pass.

I did jack it up today to see if I could do anything with the parking brake adjuster, but my tools don't fit down the hex hole and the boots on the pins look perished, so I think it's game over there.

If you're reading this, do you want to know more? Would pictures help?

)

)

)

)

)

)